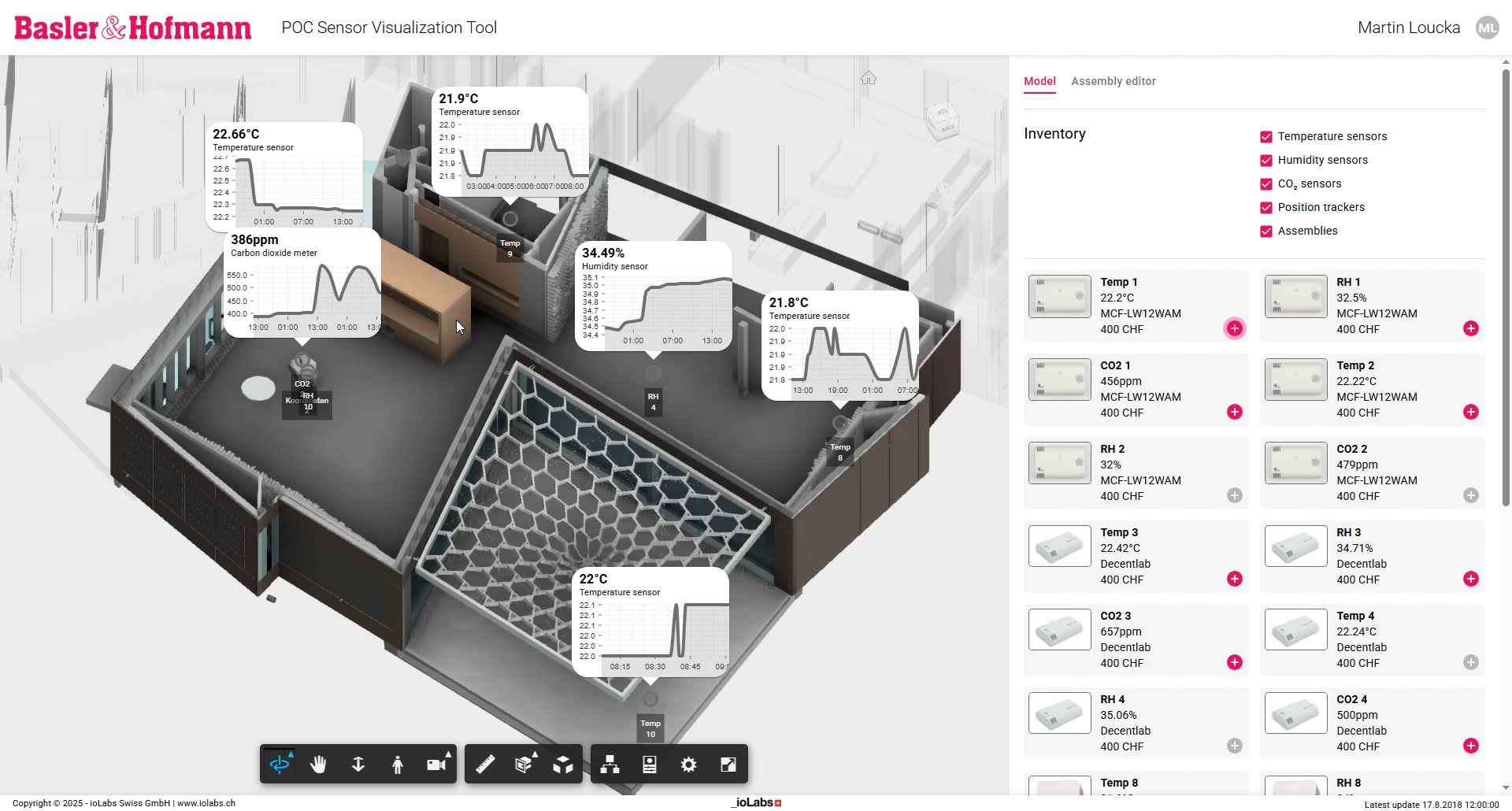

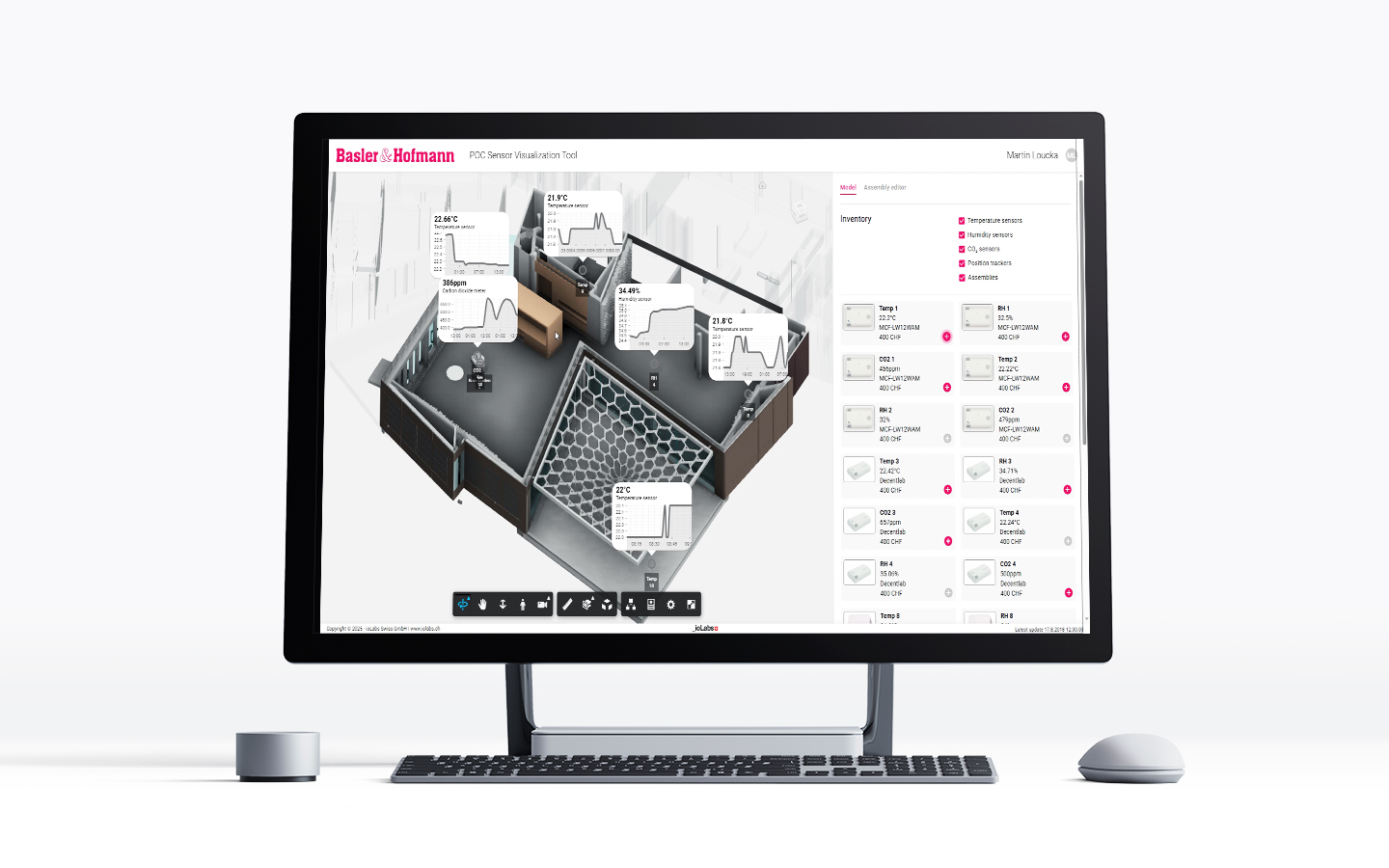

Basler & Hofmann AG required a web-accessible digital twin of their building, rendered with a high degree of visual fidelity using the Autodesk Forge Viewer. Beyond the digital twin, the solution needed to integrate real-time sensor data directly within the model, displaying both current and historical values at their exact physical locations. A further requirement was the ability to customize the visual representation of each sensor type within the digital environment.

The primary objective was to deliver a digital twin that allowed seamless interaction with building sensors, including dynamic placement, modification, and removal of devices within the 3D model. Additionally, the system had to support composite assemblies - for instance, mobile units such as robotic devices equipped with multiple sensors - and track their movement and data streams in real time. This required not only precise visualization but also a robust back-end architecture capable of supporting live updates, spatial context, and user-driven configuration.

Solution

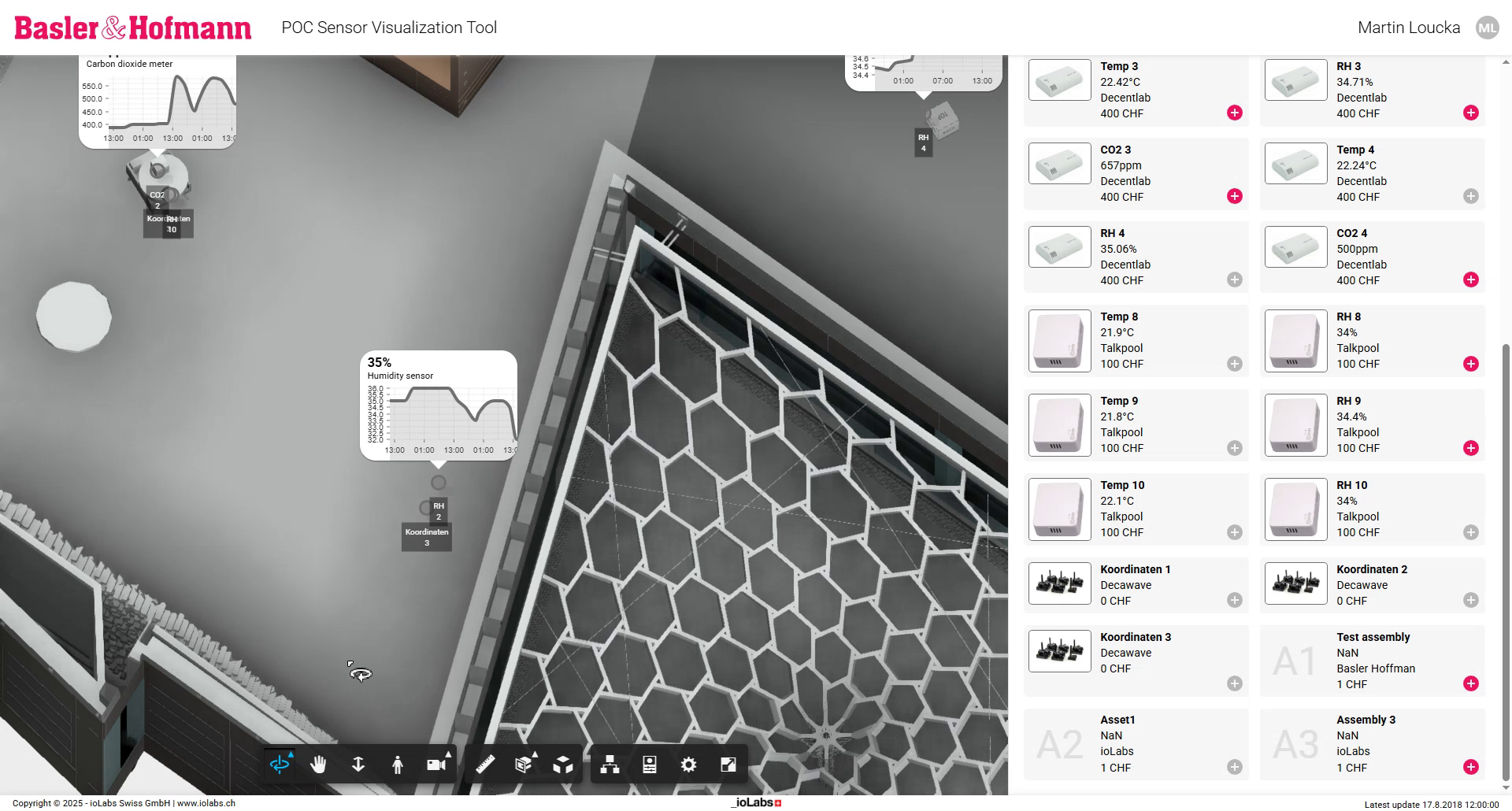

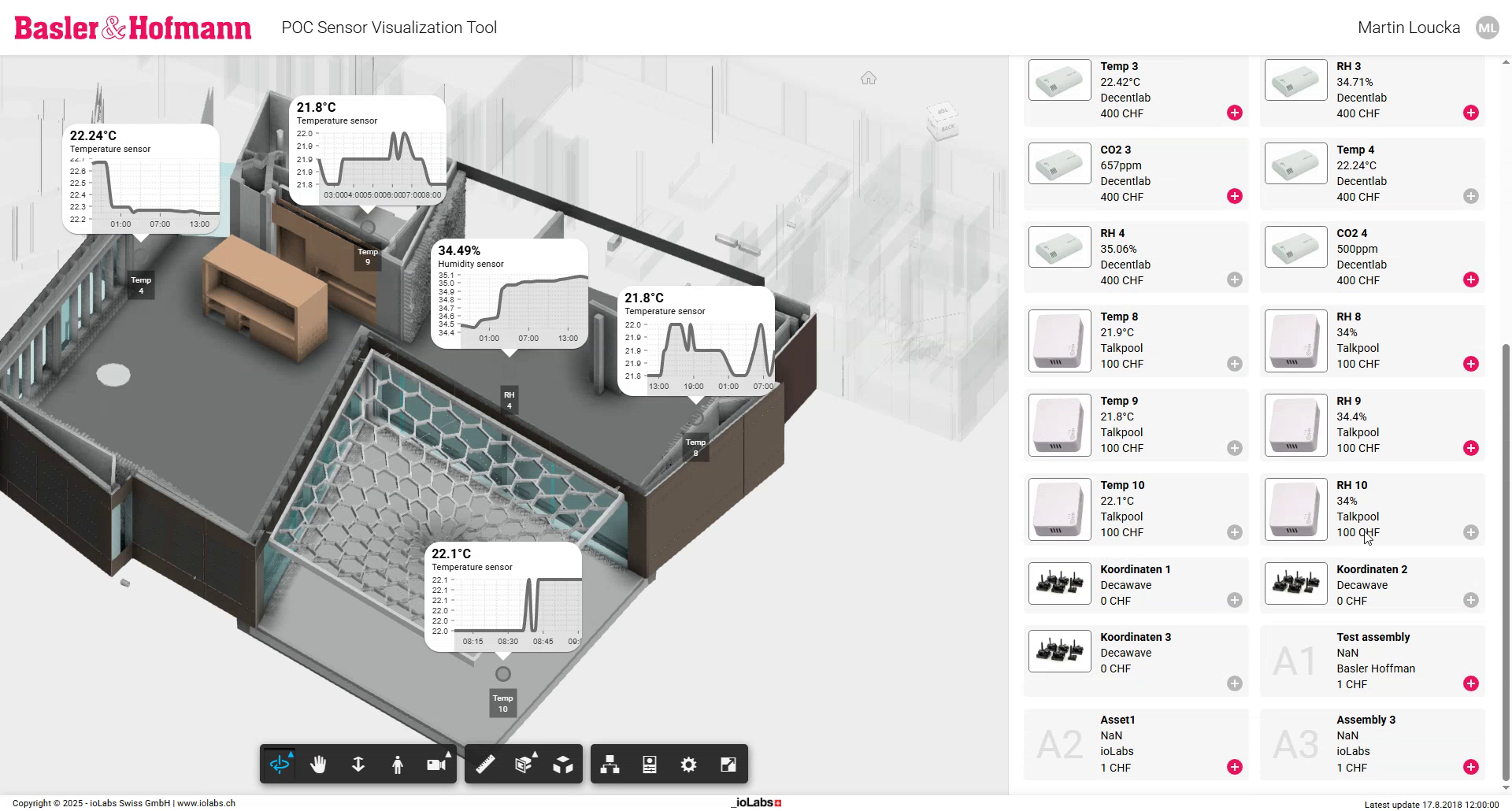

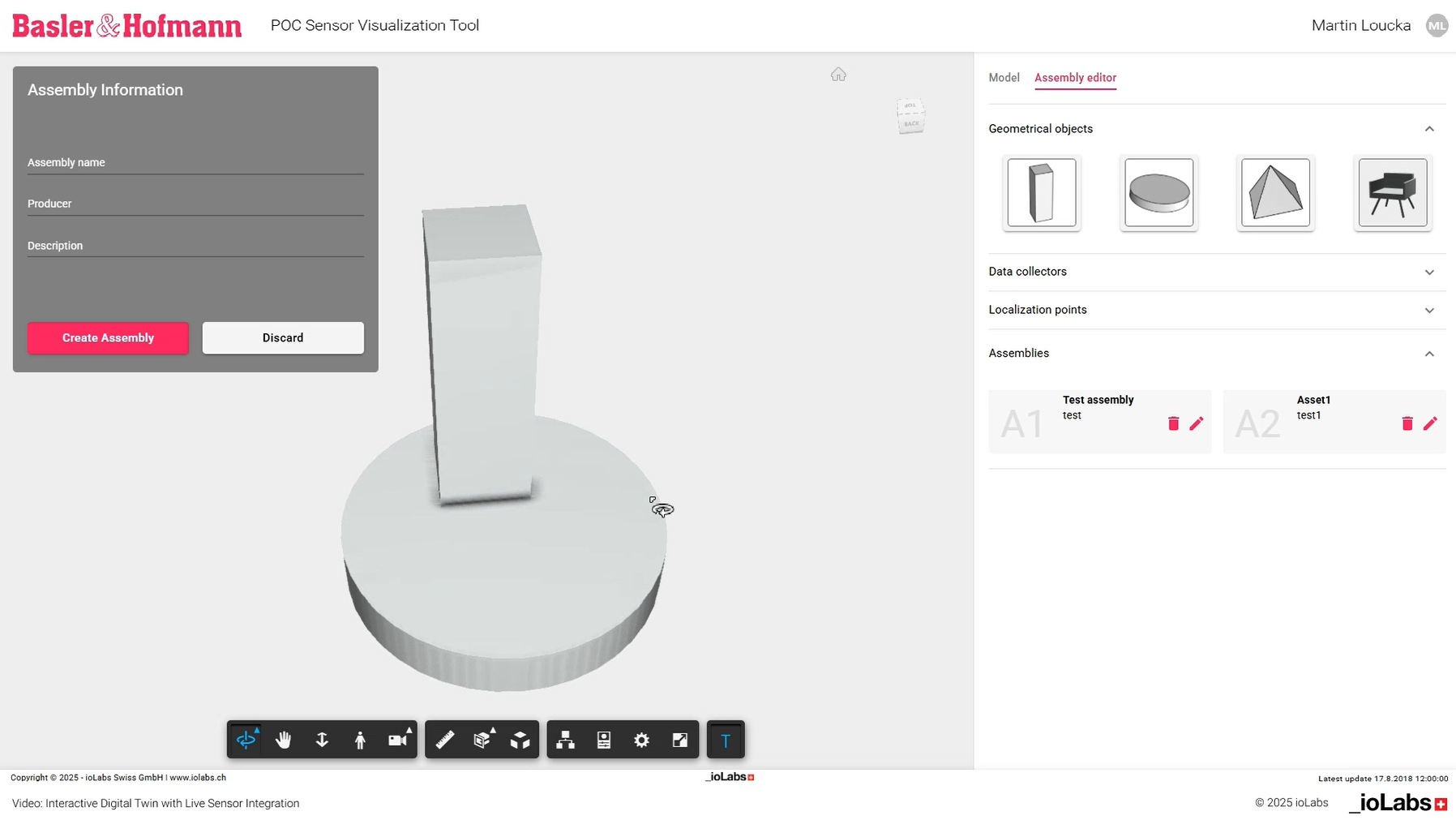

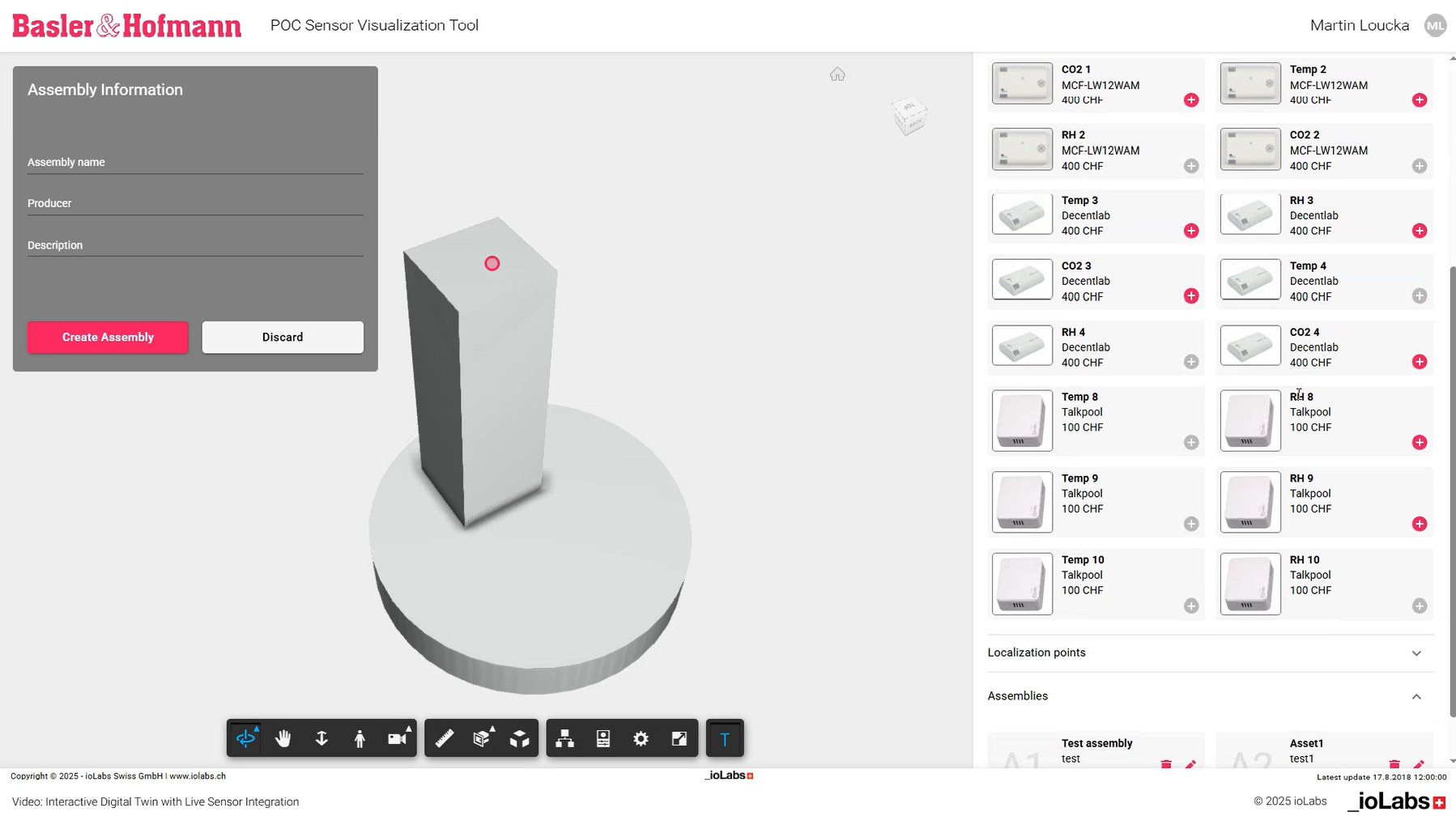

The resulting application is a fully browser-based digital twin system that combines high-performance 3D visualization with real-time data integration and an intuitive user interface. Users can insert new sensors into the model by selecting them from a virtual inventory and placing them in the appropriate location via drag-and-drop. Sensor positions can be subsequently adjusted or removed, with removed sensors returned to inventory for future reuse. The interface is designed to be accessible to non-technical users while maintaining full control over spatial configuration.

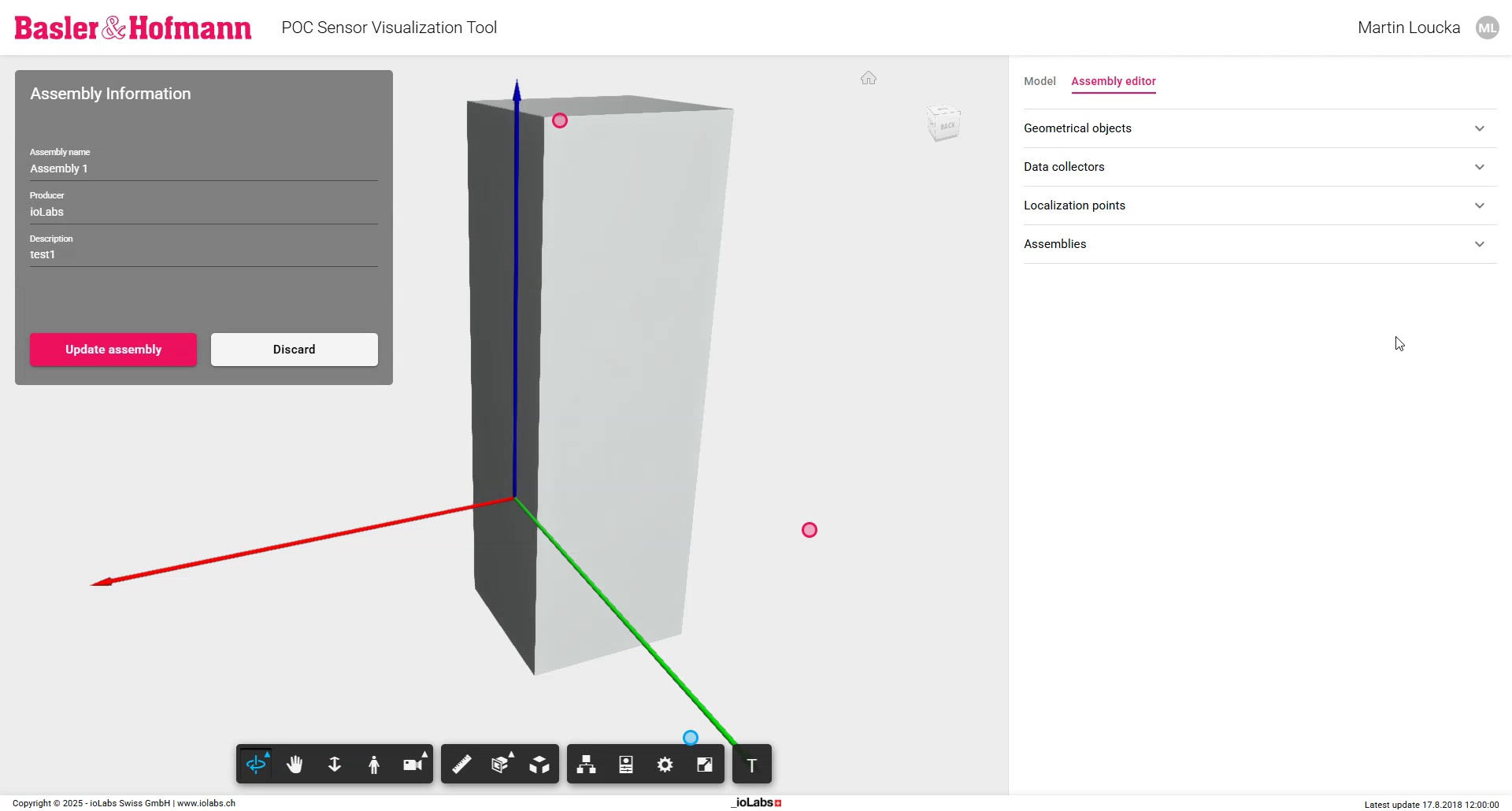

A key feature of the solution is its support for sensor assemblies. Users can create custom visual objects or group existing model components, such as furniture or equipment, and attach one or more sensors to them. These assemblies support live position tracking, enabling the monitoring of mobile devices as they move through the environment. Sensor readings remain associated with the assemblies and are updated in real time, ensuring accurate representation of both data and location.

The platform supports both real-time and historical data visualization, with the ability to toggle views and adjust the styling of individual sensor types. All interactions occur within the Autodesk Forge Viewer, ensuring cross-platform compatibility and eliminating the need for additional software installation.

Outcome

The implemented solution delivers a scalable, maintainable, and user-centric platform for managing and visualizing sensor data within a digital twin. By embedding contextual information directly within the 3D model, it enhances situational awareness, facilitates data-driven decision-making, and significantly reduces the effort required to manage sensor infrastructure. The extensibility of the system, including support for mobile assemblies and real-time tracking, positions it for a broad range of future applications, from automated maintenance systems to environmental monitoring and asset management.

Video

Gallery

Client

Basler & Hofmann AG

Credits

ioLabs AG

|

Technology

ioFramework

Autodesk Forge Viewer

.Net Core

C#

React

Typescript

ACC

Navisworks

MQTT

|