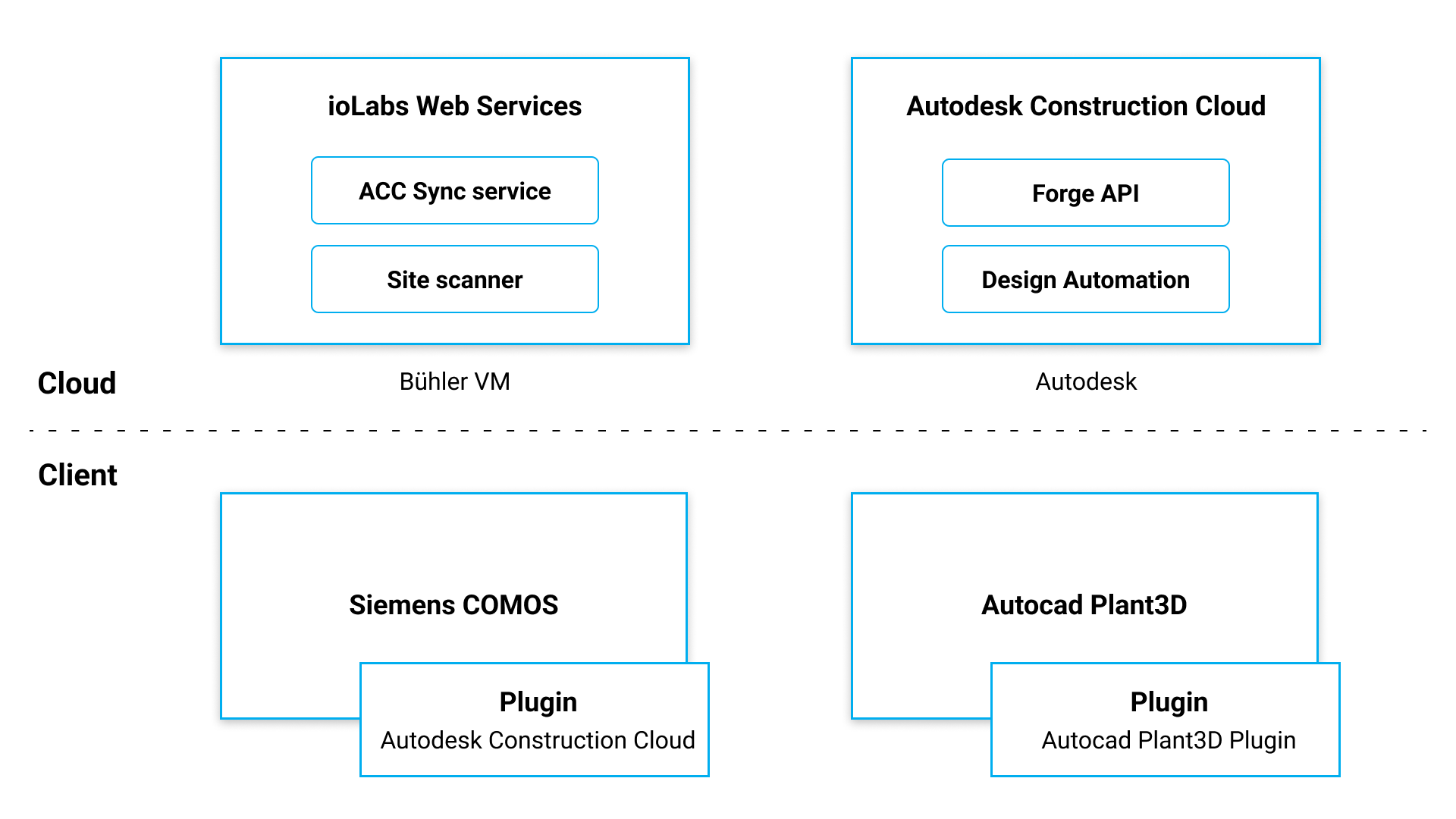

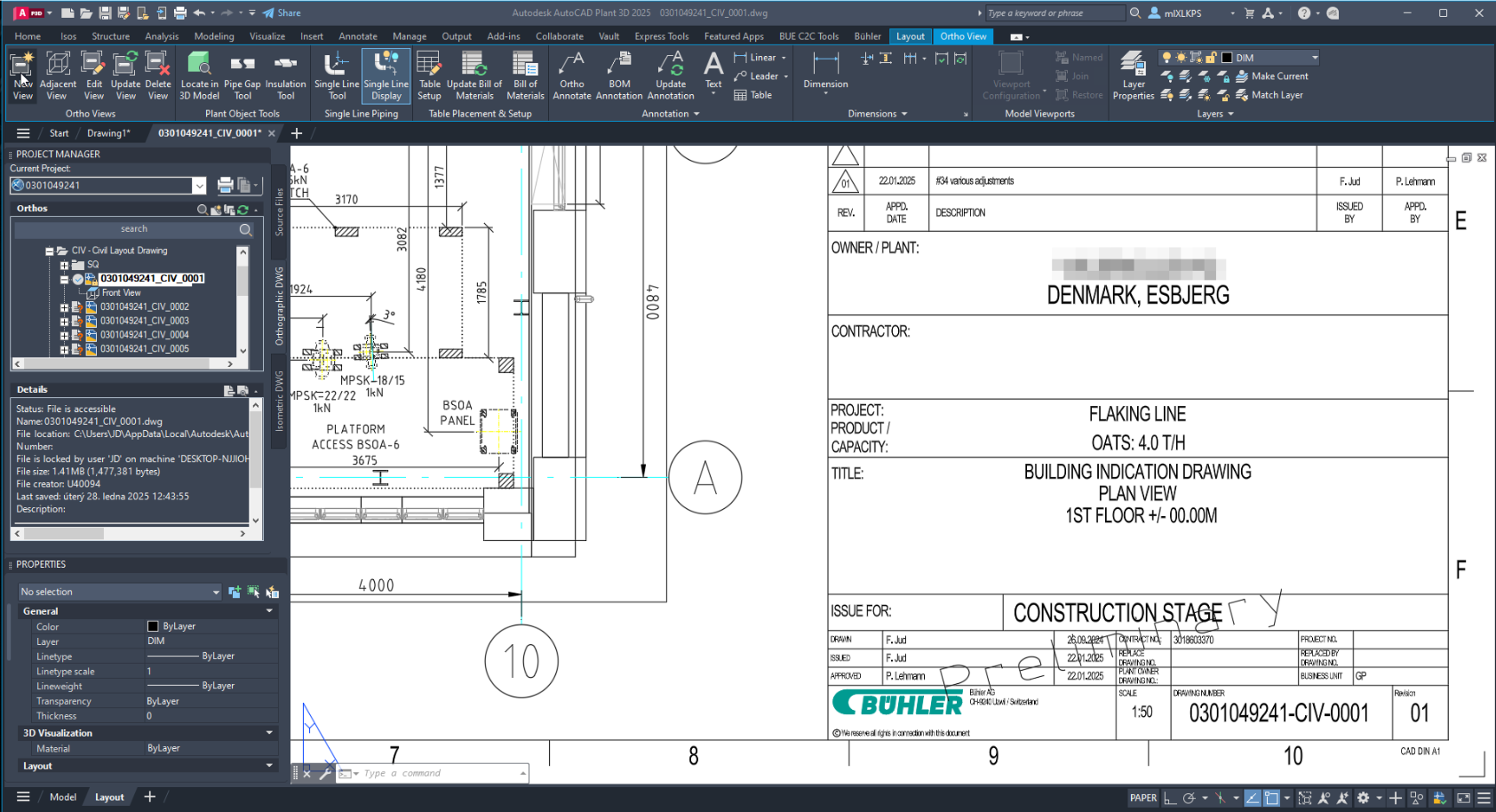

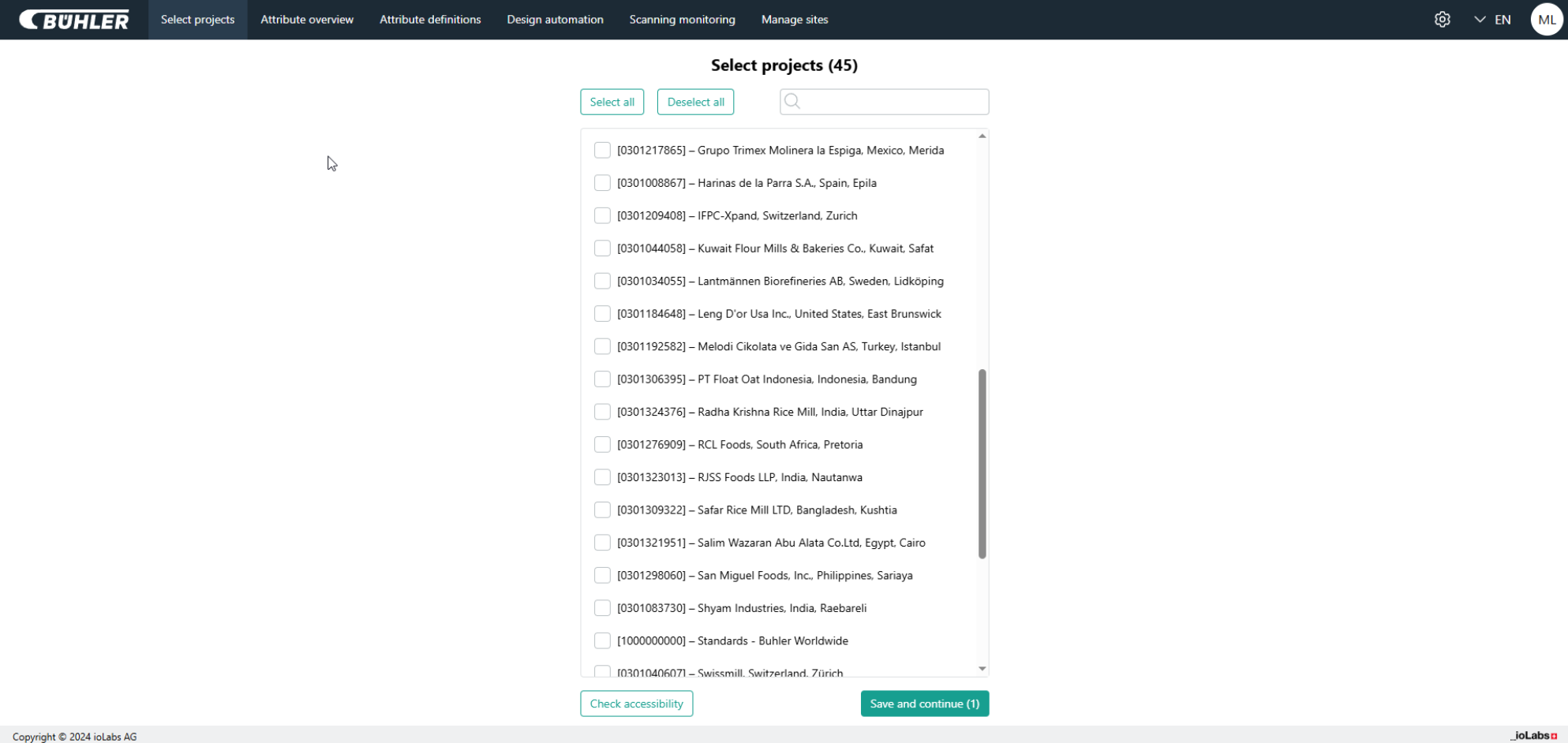

Bühler AG, a global technology partner for food and advanced materials processing, sought to enhance the efficiency and consistency of its engineering workflows by implementing automation across Autodesk Plant3D and Autodesk Construction Cloud (ACC). With thousands of new projects initiated annually, Bühler required a robust and scalable solution to support its global operations. In collaboration with ioLabs, a comprehensive suite of web-based tools - collectively referred to as Bühler Web Services - was developed to meet these requirements.

Every month

10k

PDFs are created

Bühler AG creates

2k

projects per year

Project managers worldwide

300

using the implemented tools daily

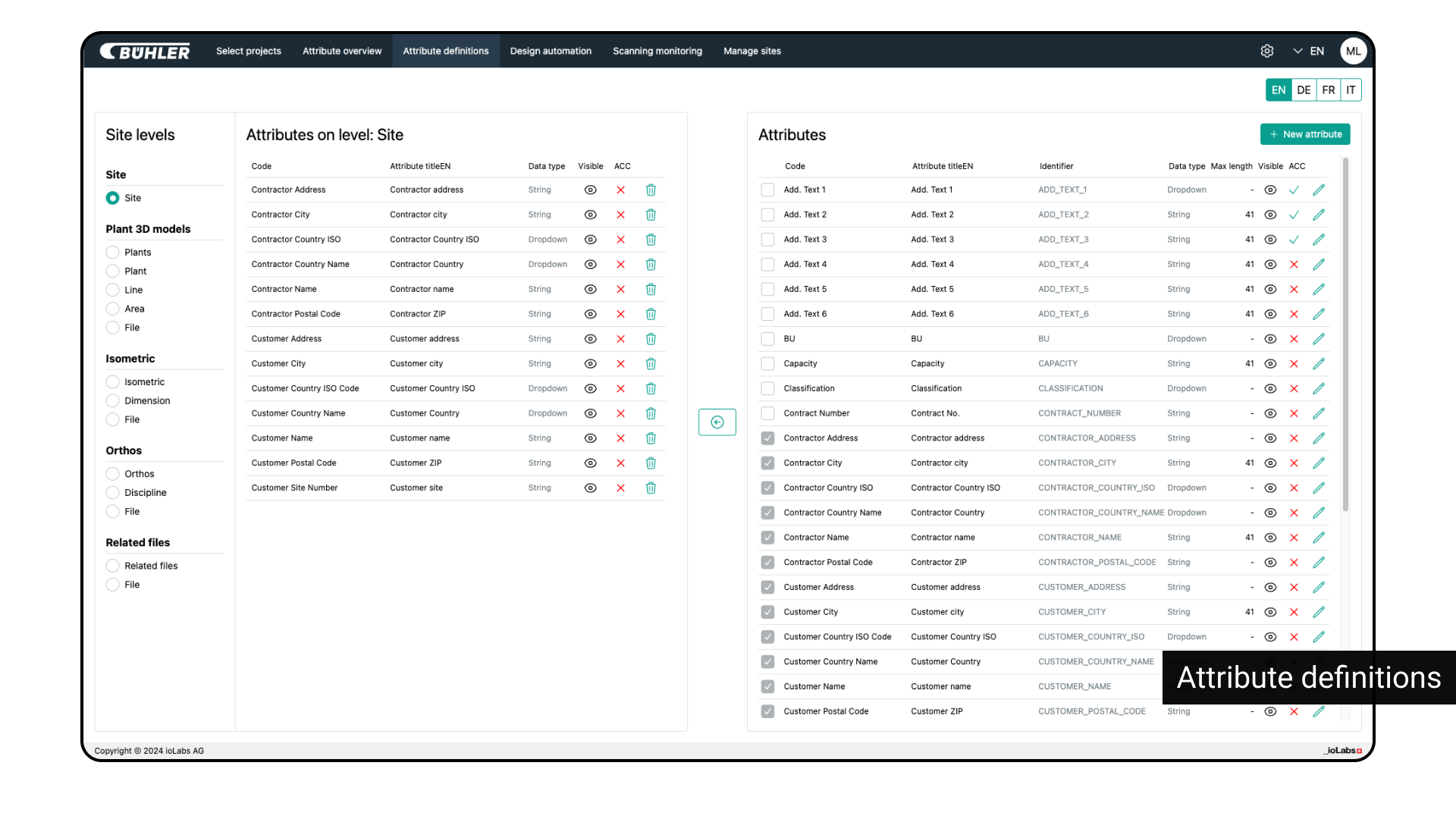

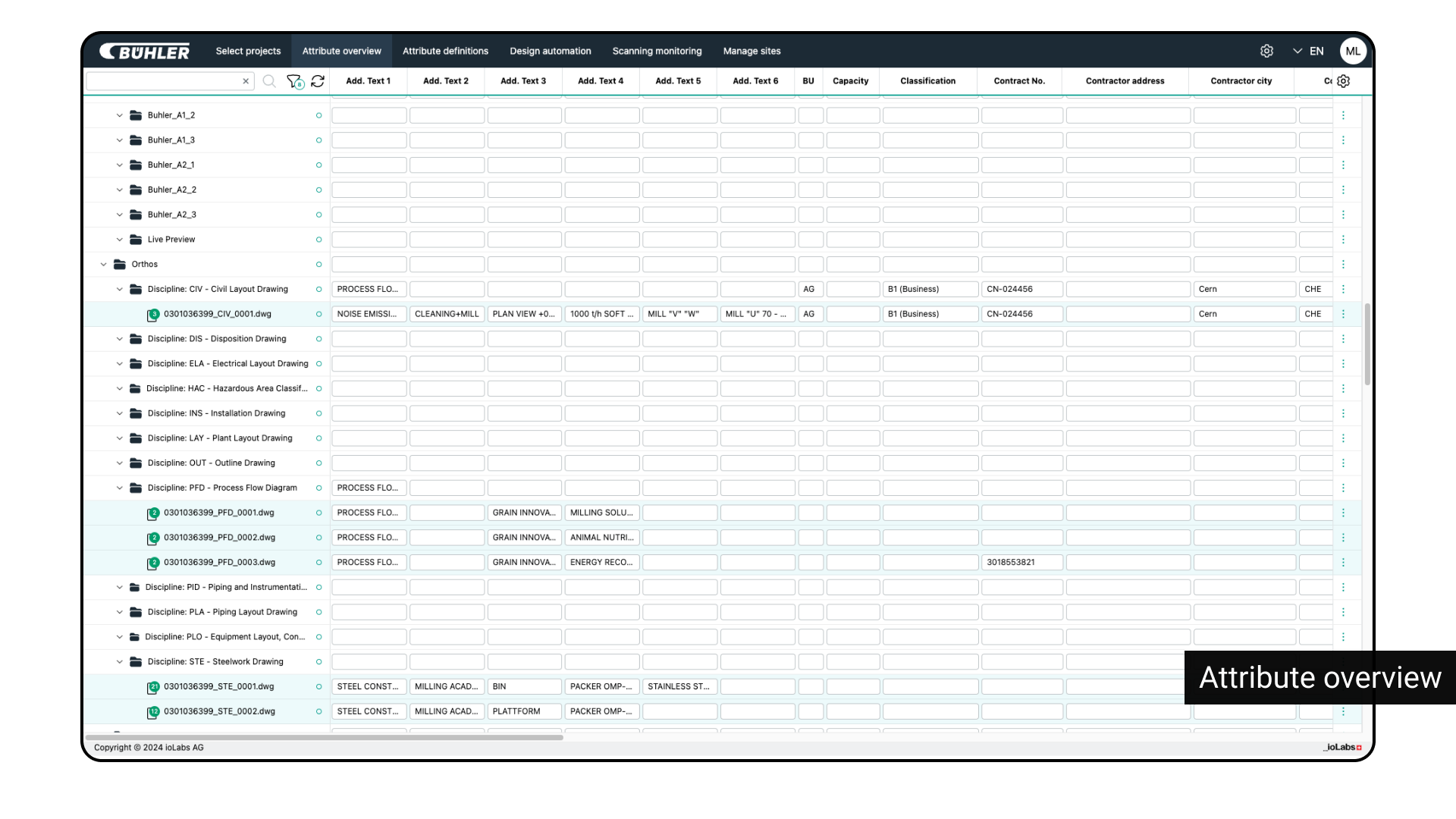

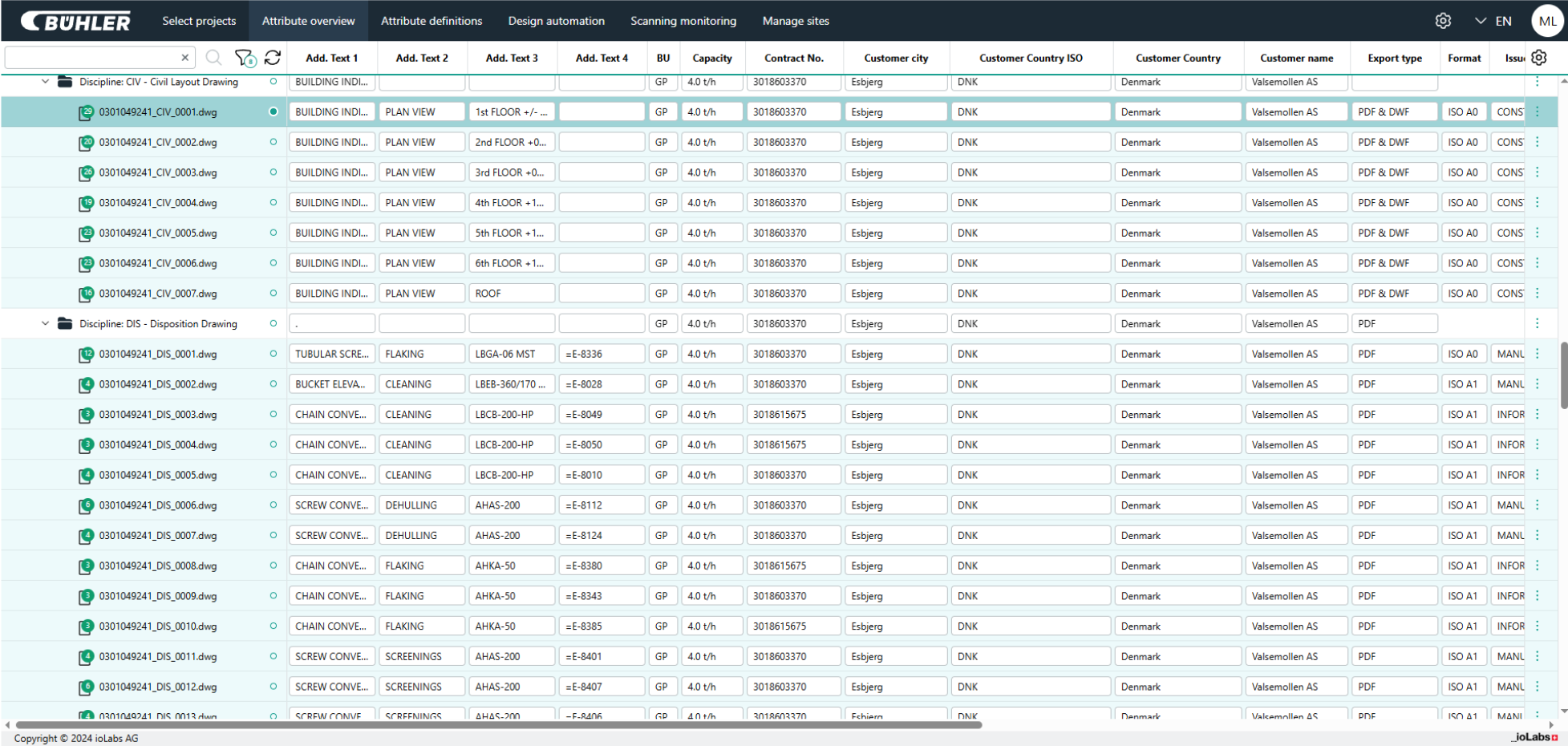

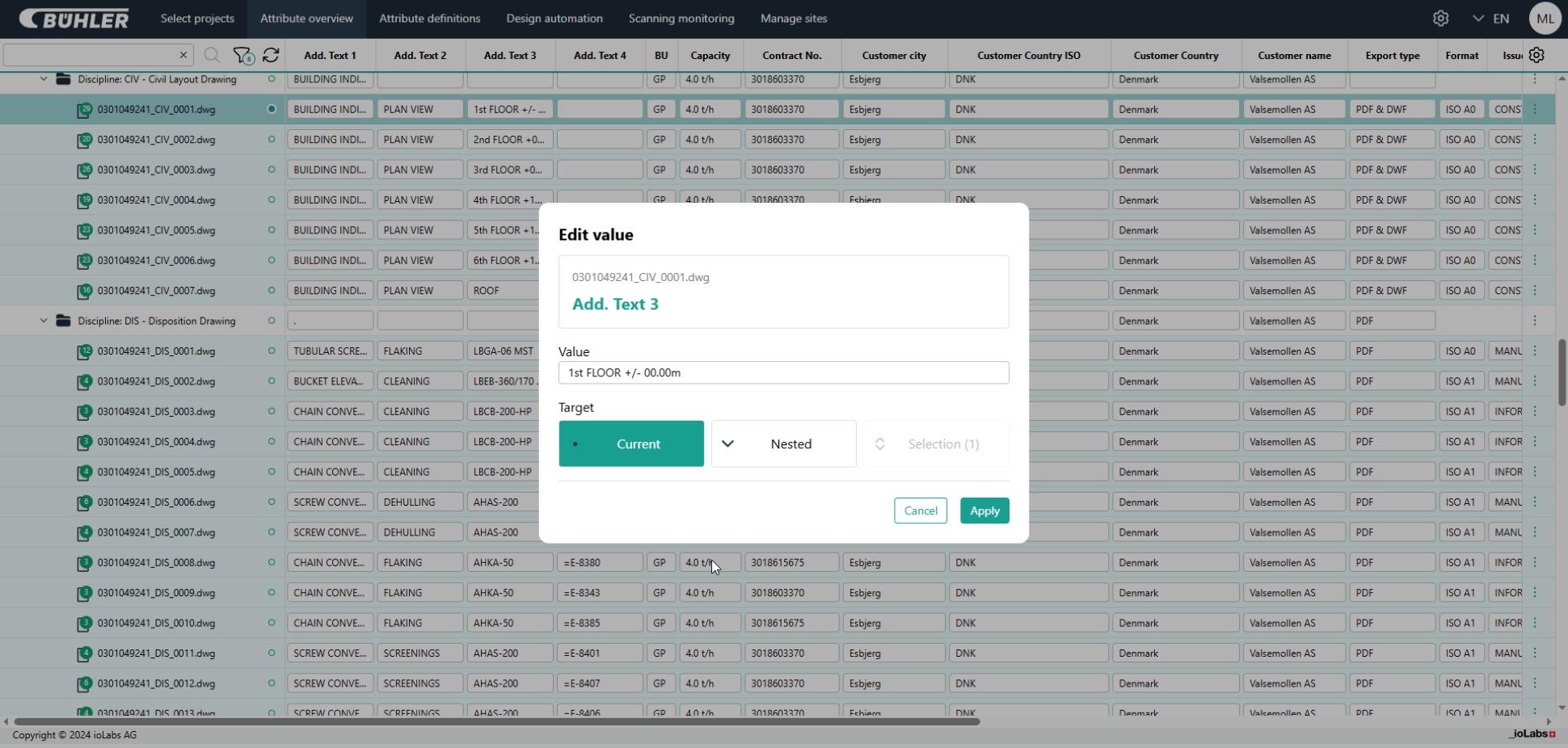

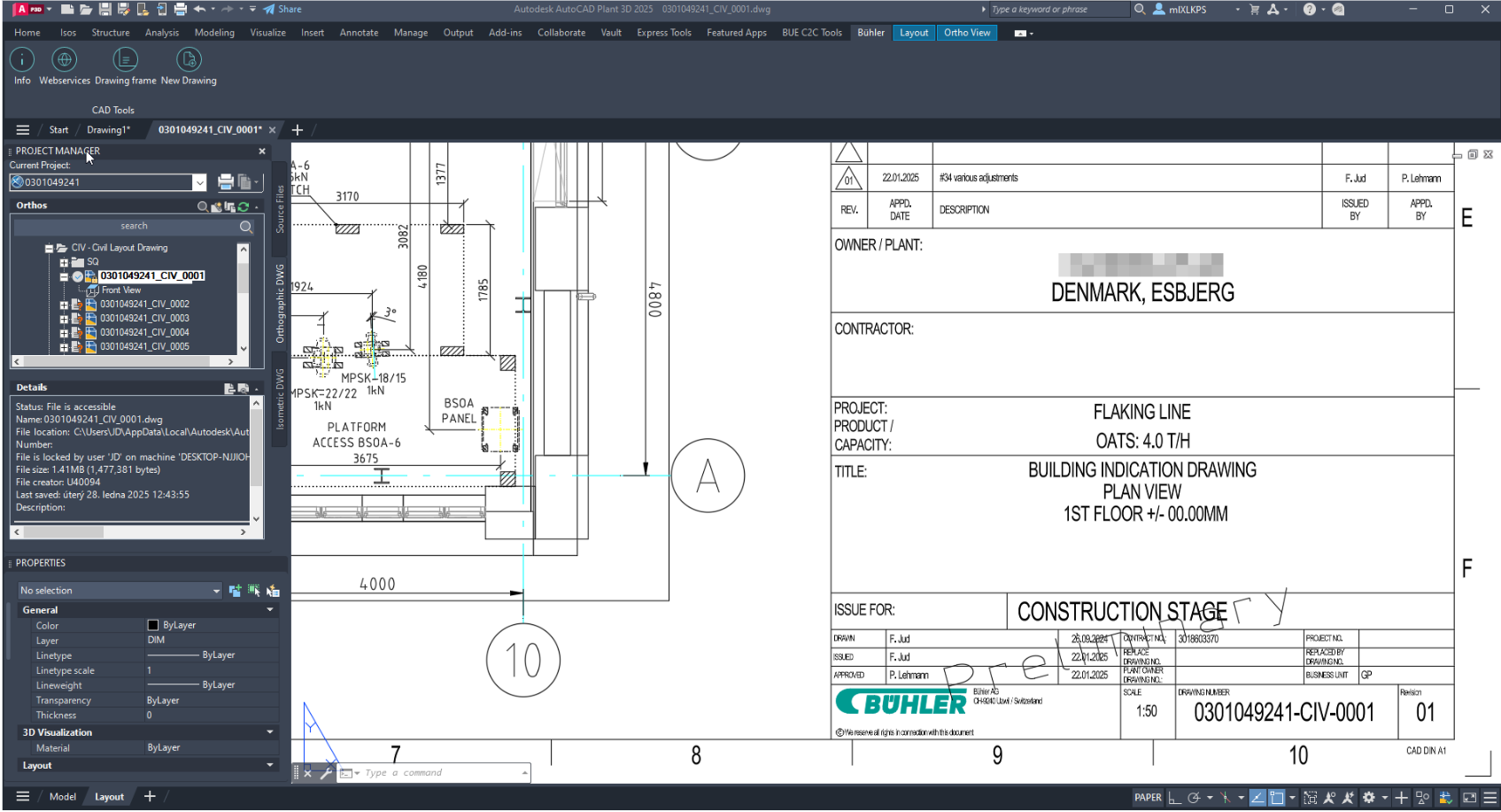

Prior to automation, project teams with over 1200 users were required to complete numerous repetitive tasks manually. Attribute values had to be updated individually in each file, drawing frames were filled in manually - often without multilingual support - and the setup of Plant3D and ACC projects was labor-intensive. The creation of documentation such as PDFs for 1400 projects was also a manual process, which introduced risks of inconsistency. Additionally, the absence of a standardized file naming convention and the inability to apply changes across multiple documents contributed to inefficiencies and increased overhead.

The Solution

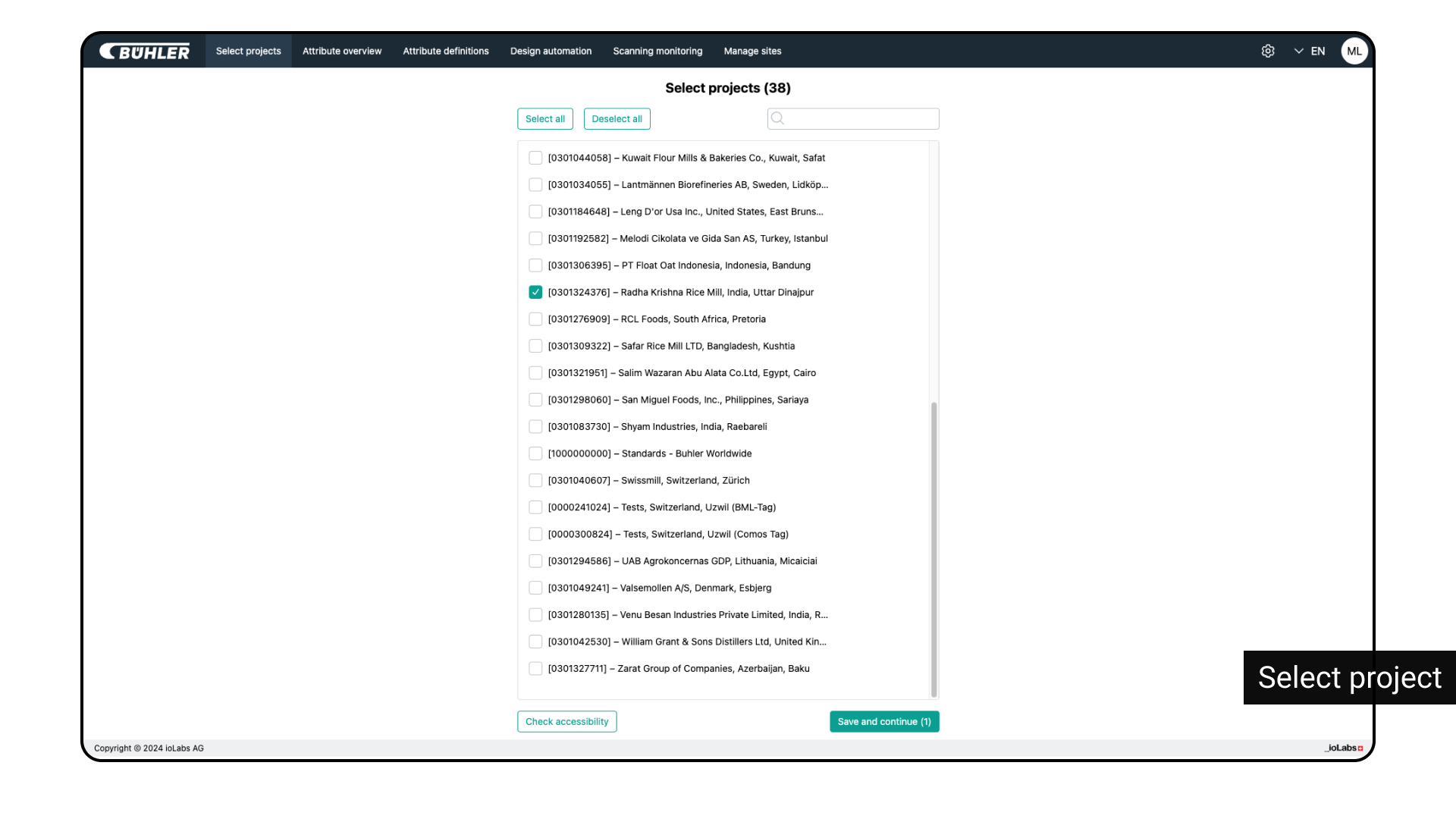

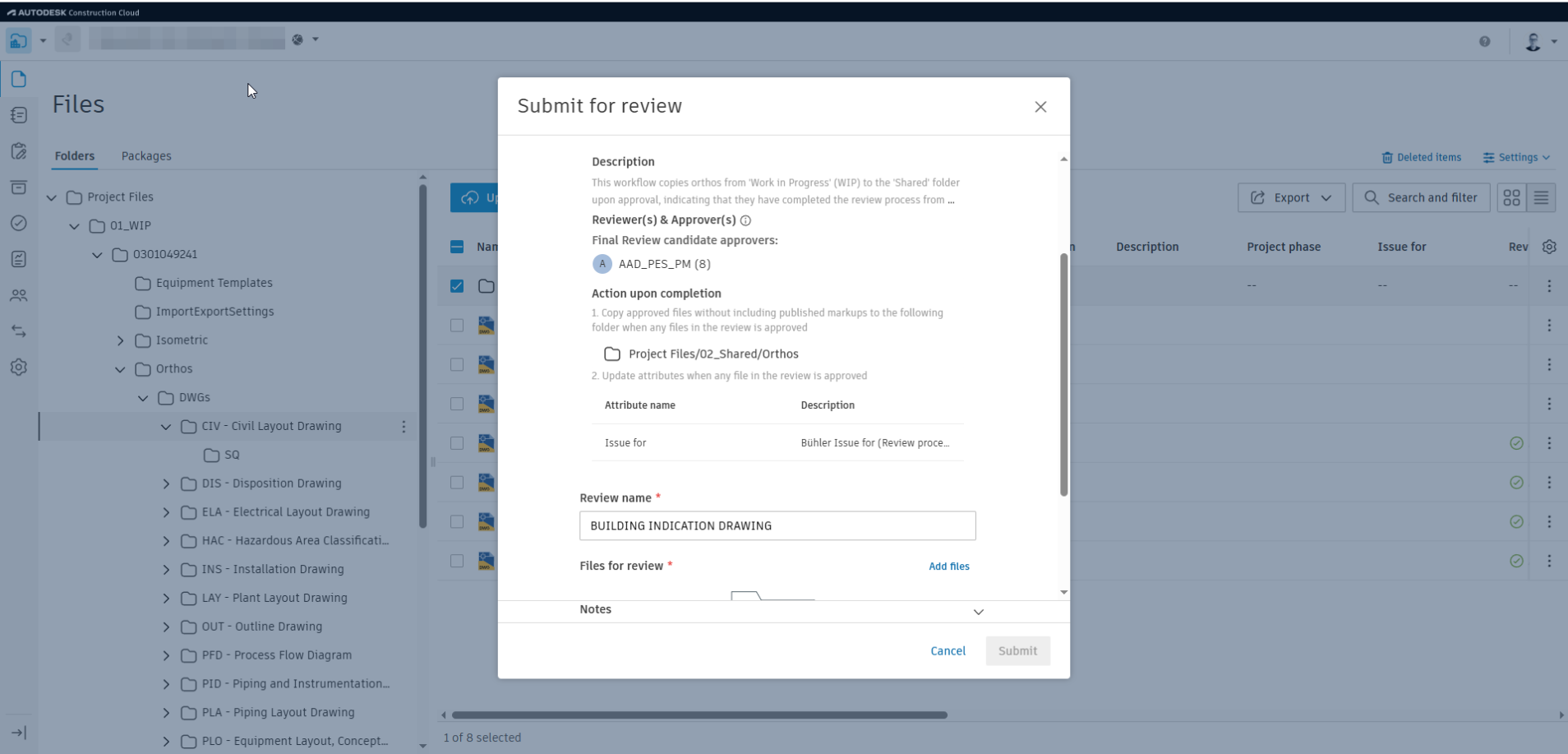

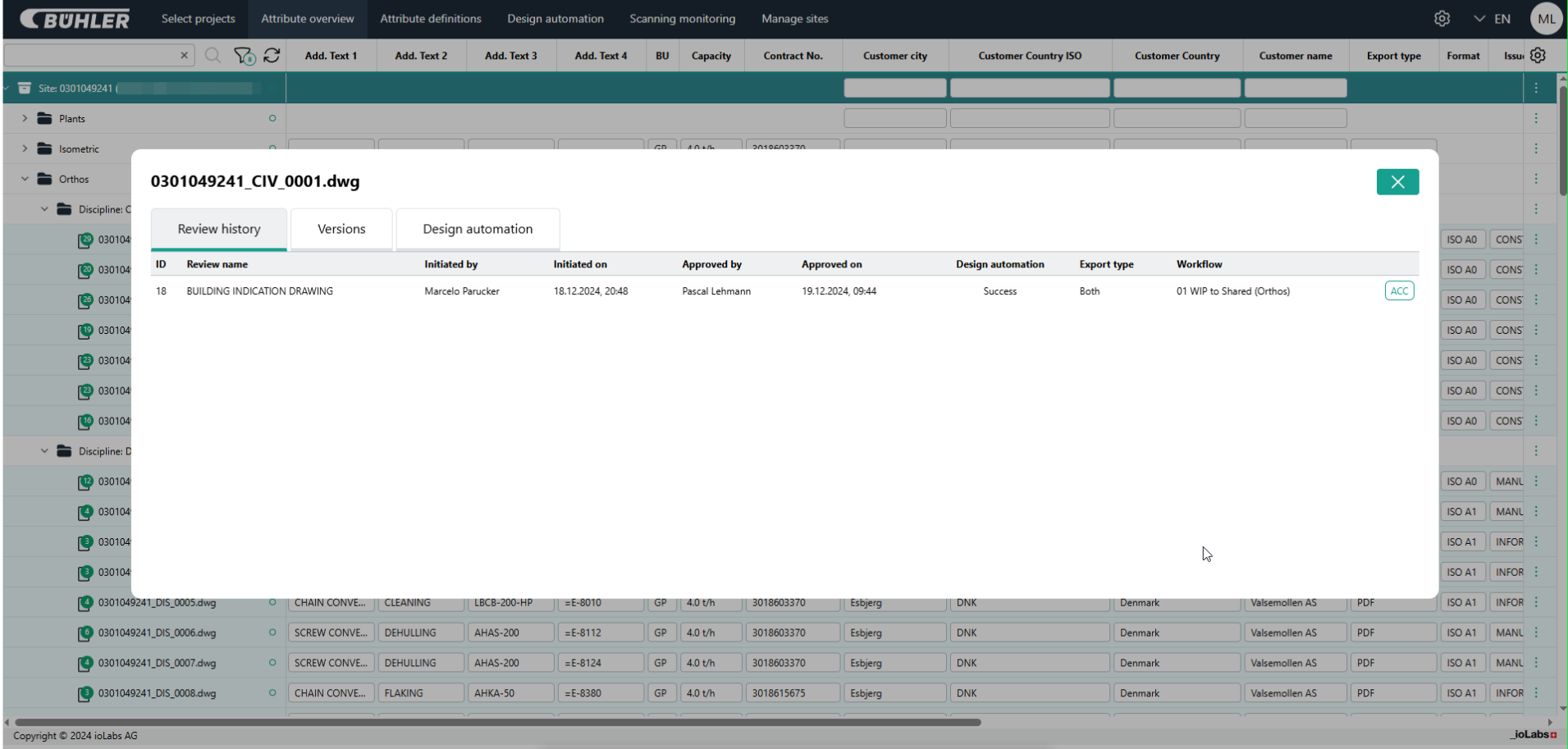

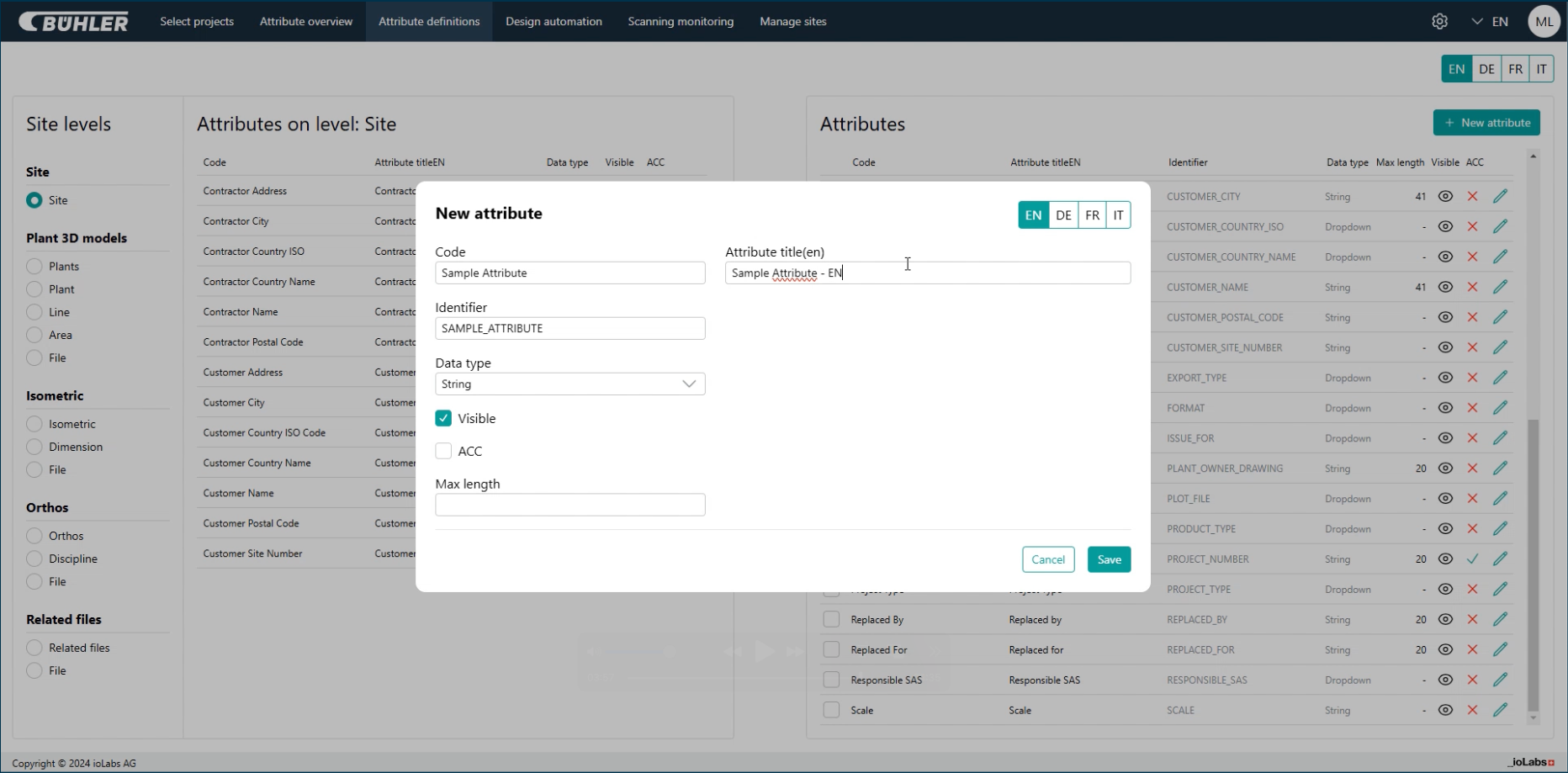

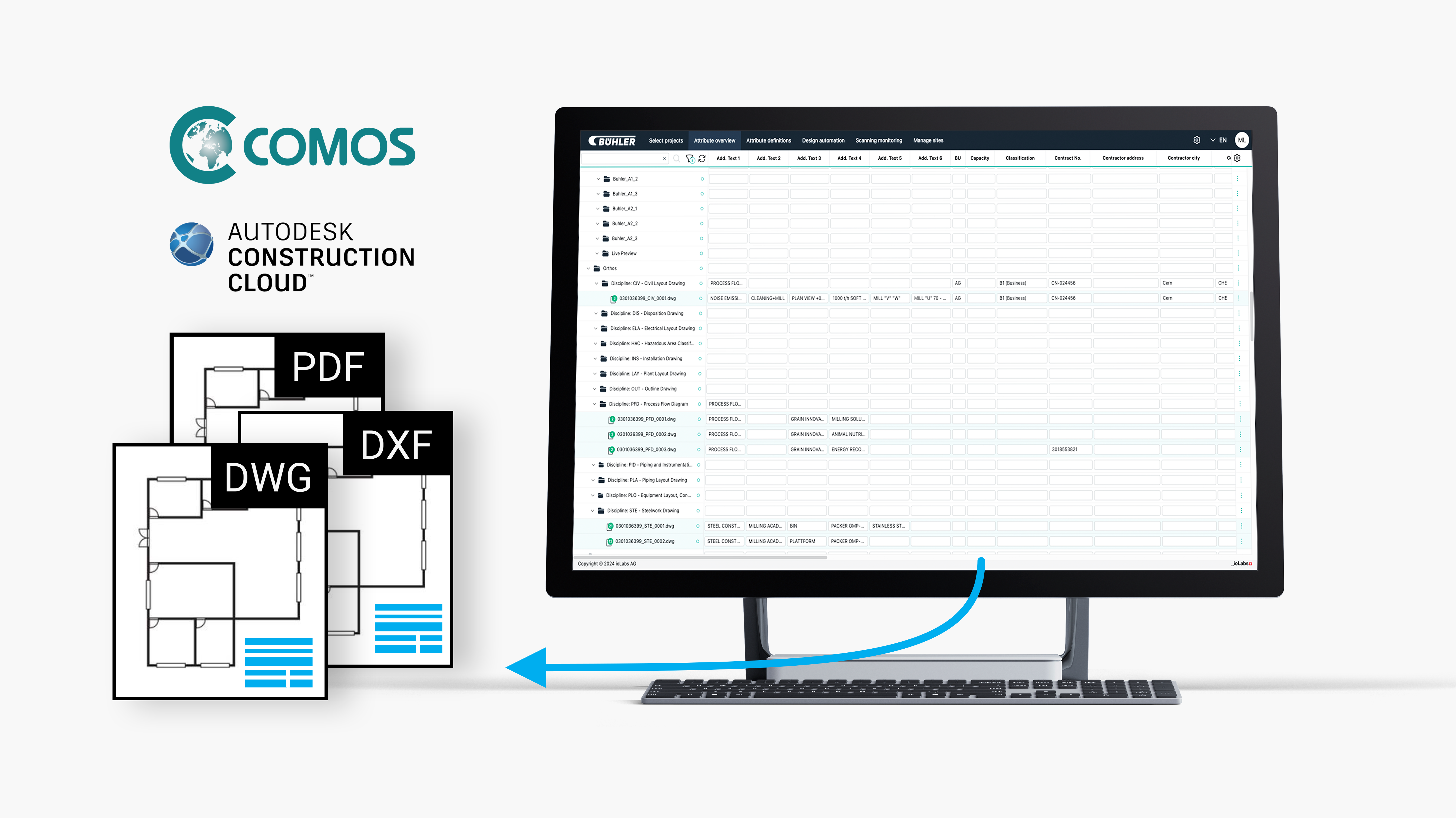

To address these challenges, ioLabs delivered a solution focused on automation, centralization, and consistency. Attributes could now be managed from a centralized interface and automatically inherited across structured project hierarchies. Engineers were provided with a unified environment to manage multiple projects in parallel, with the ability to search and edit attribute values across the dataset. The solution also enabled the creation of Plant3D projects that are fully integrated with ACC, streamlining the overall project lifecycle.

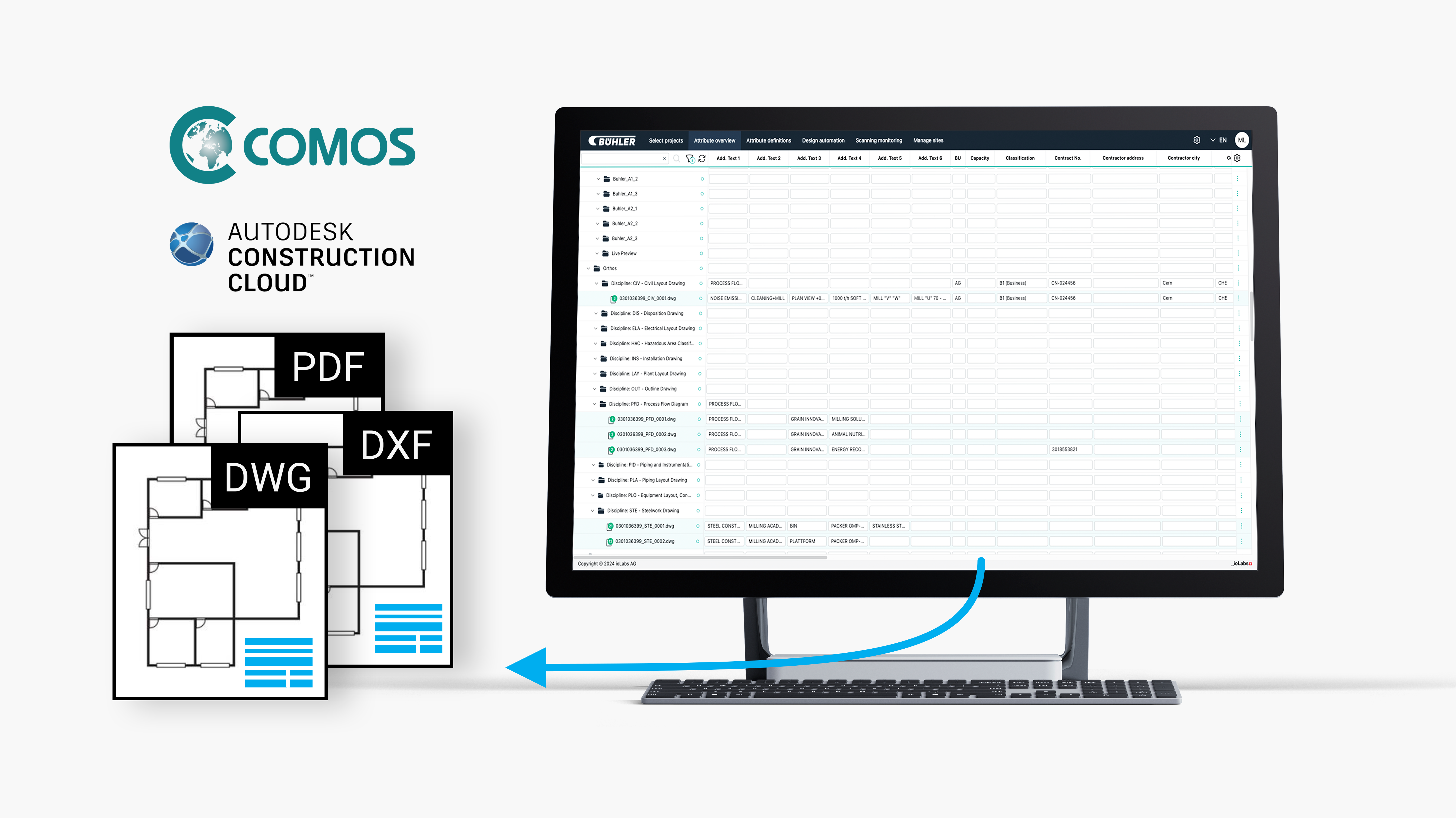

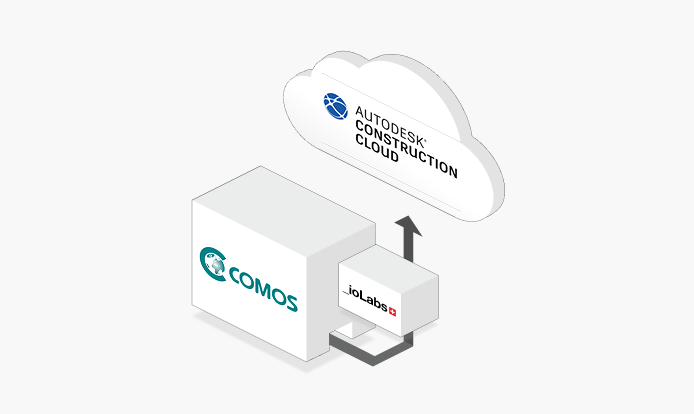

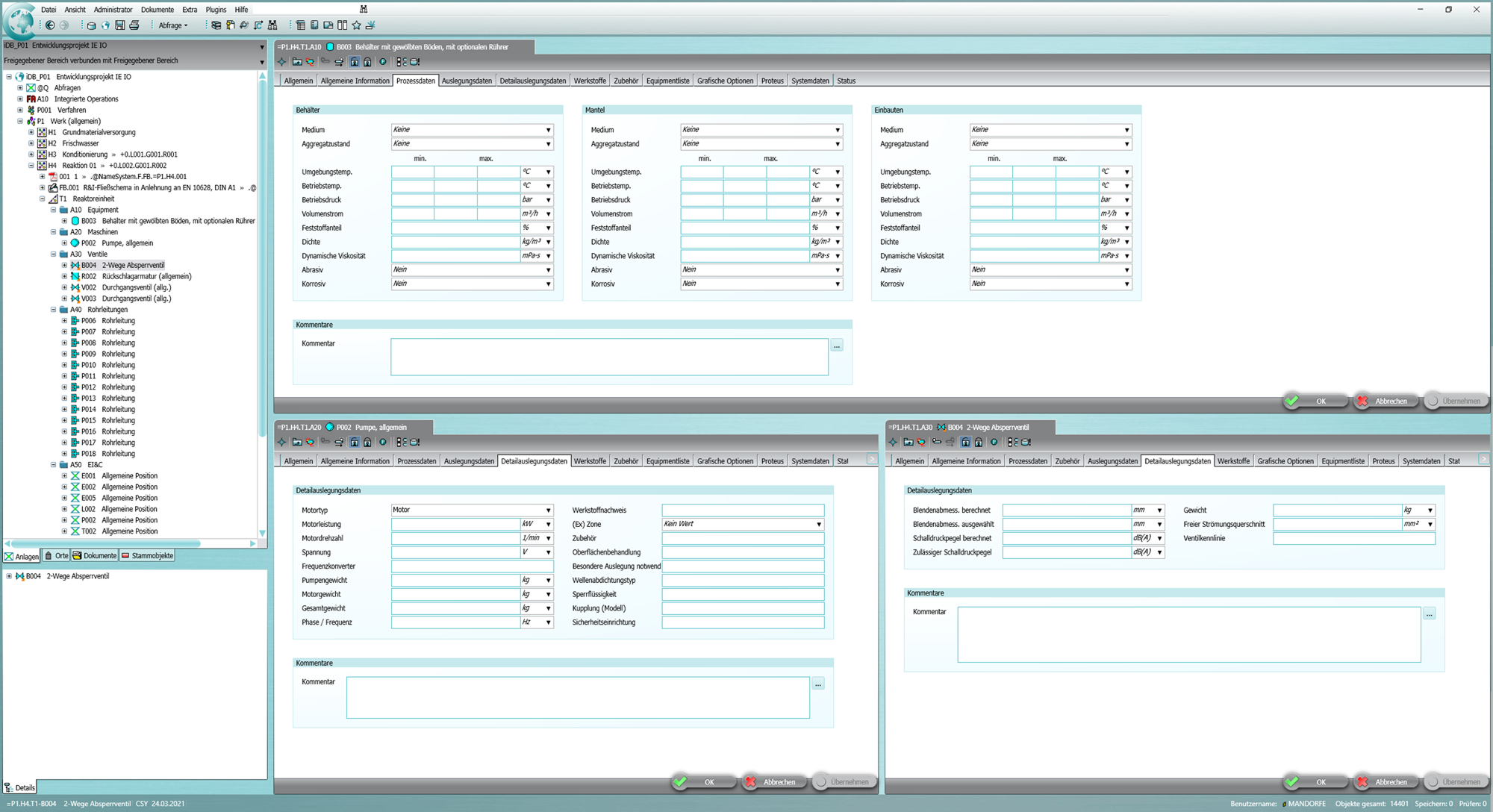

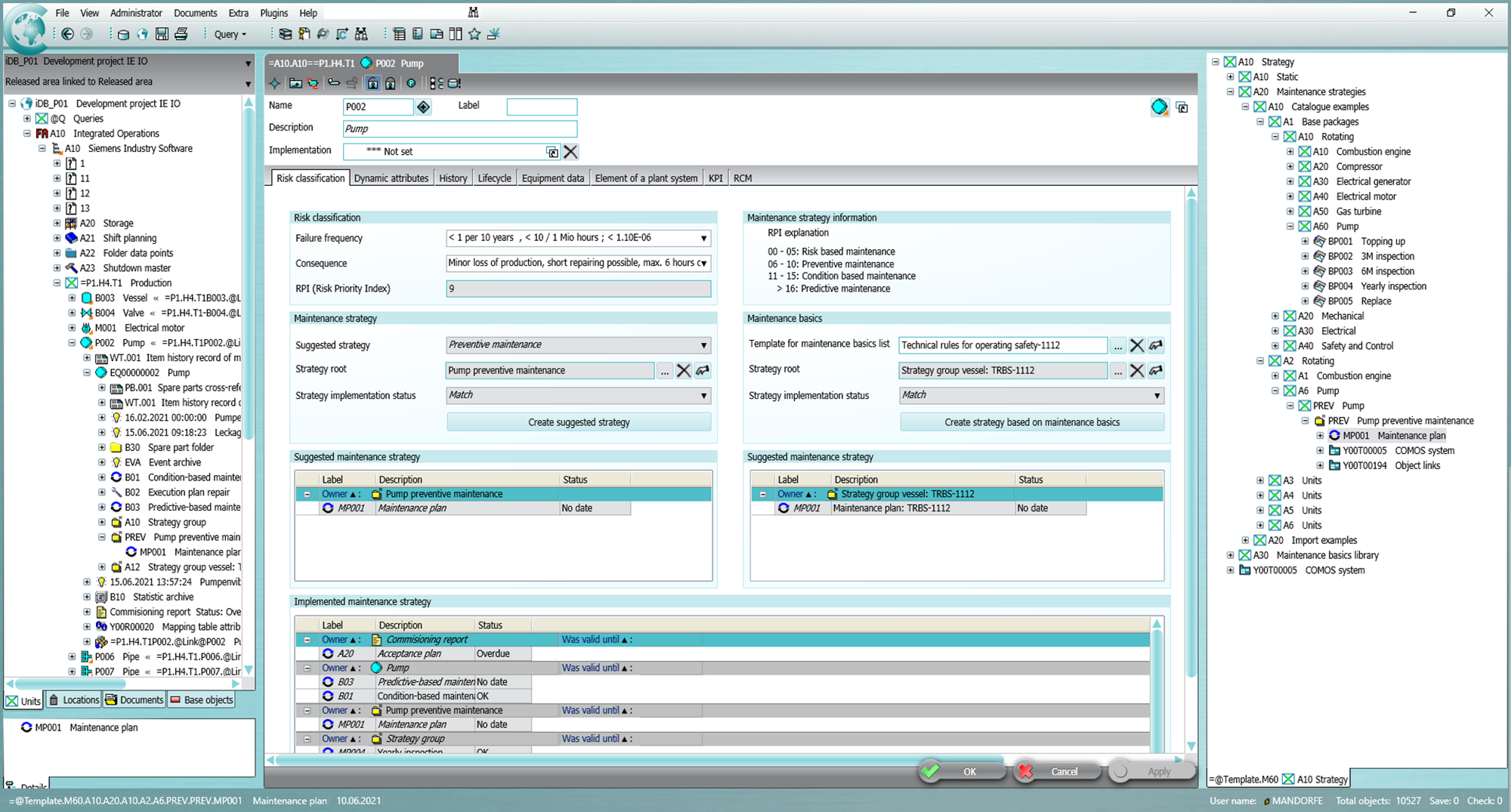

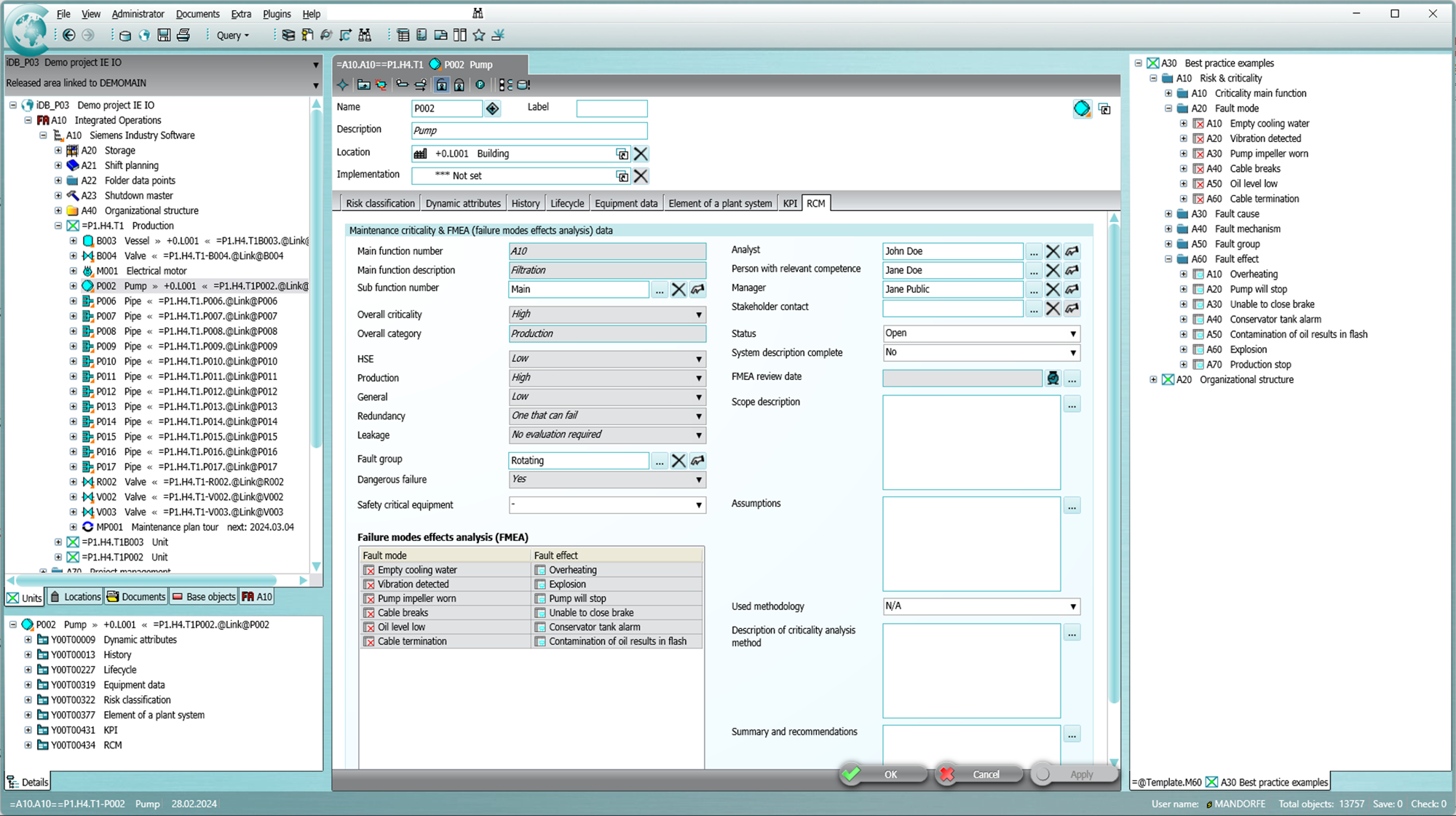

COMOS–ACC Integration

This integration bridges Siemens COMOS and Autodesk Construction Cloud (ACC), addressing the need for standardized, automated document handling. Clients often face challenges with consistent file naming, version control, and manual uploads—issues that lead to inefficiencies and errors.

As part of the solution, ioLabs implemented a seamless two-component integration: a COMOS plugin (DLL) for real-time document name generation, and a background service for queue processing and file uploads. Together, these components automatically generate document numbers based on predefined rules, upload files to ACC via the ioWS interface, and write back file identifiers into COMOS—ensuring data consistency and traceability throughout.

Key Capabilities

- Automated Naming Convention Enforcement – Generates unique document names using customizable rules and counters per project and document type.

- Asynchronous Background Uploads – Files queued in COMOS are automatically uploaded to ACC; success or failure is reported back, keeping metadata in sync.

- REST API Feedback Loop – Updates COMOS fields (ACC link, counter, error code) after each upload, maintaining full traceability.

- Client-Specific Configuration – Supports customized rules for naming, upload targets, and metadata mapping.

Process Improvements

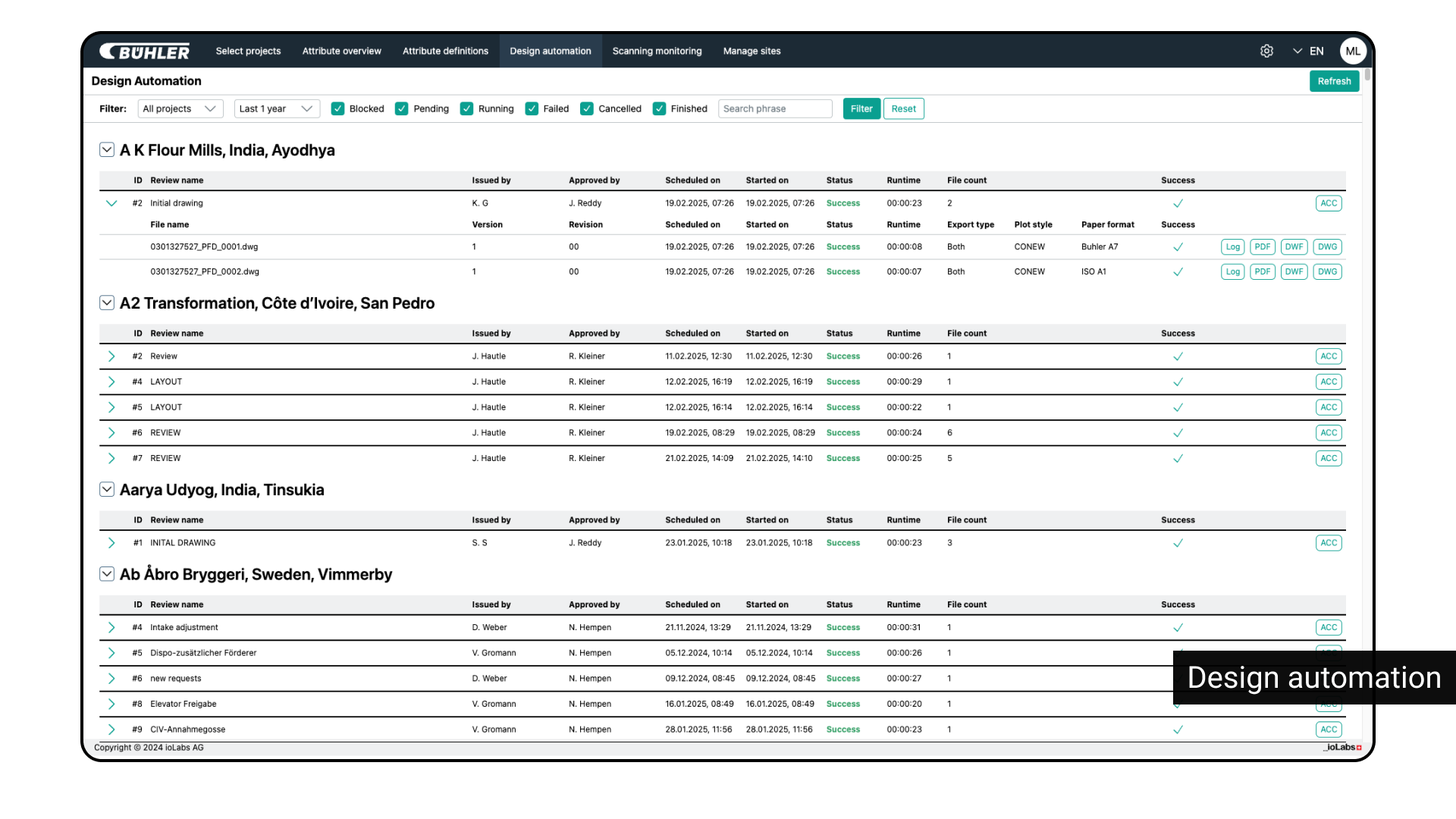

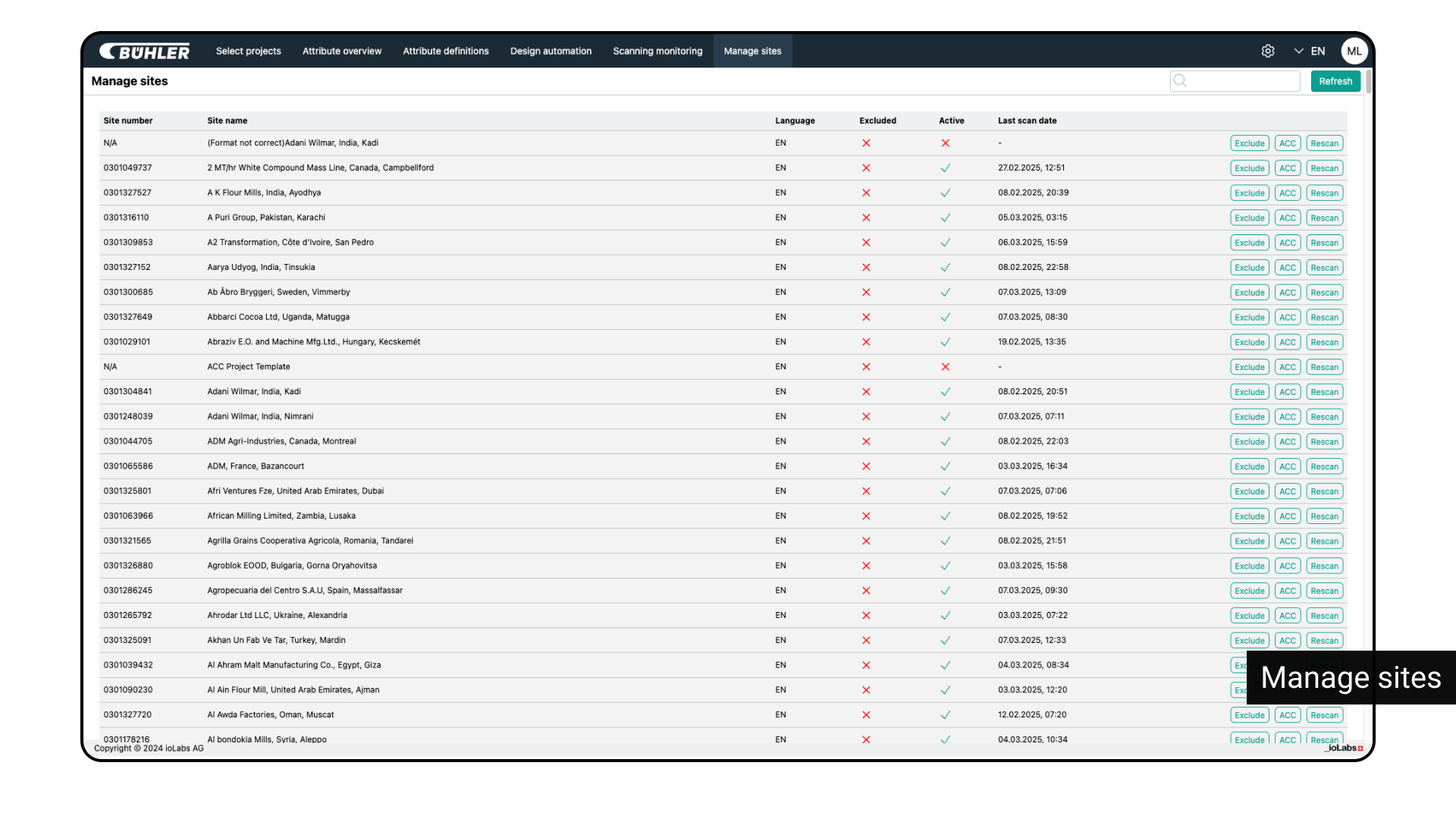

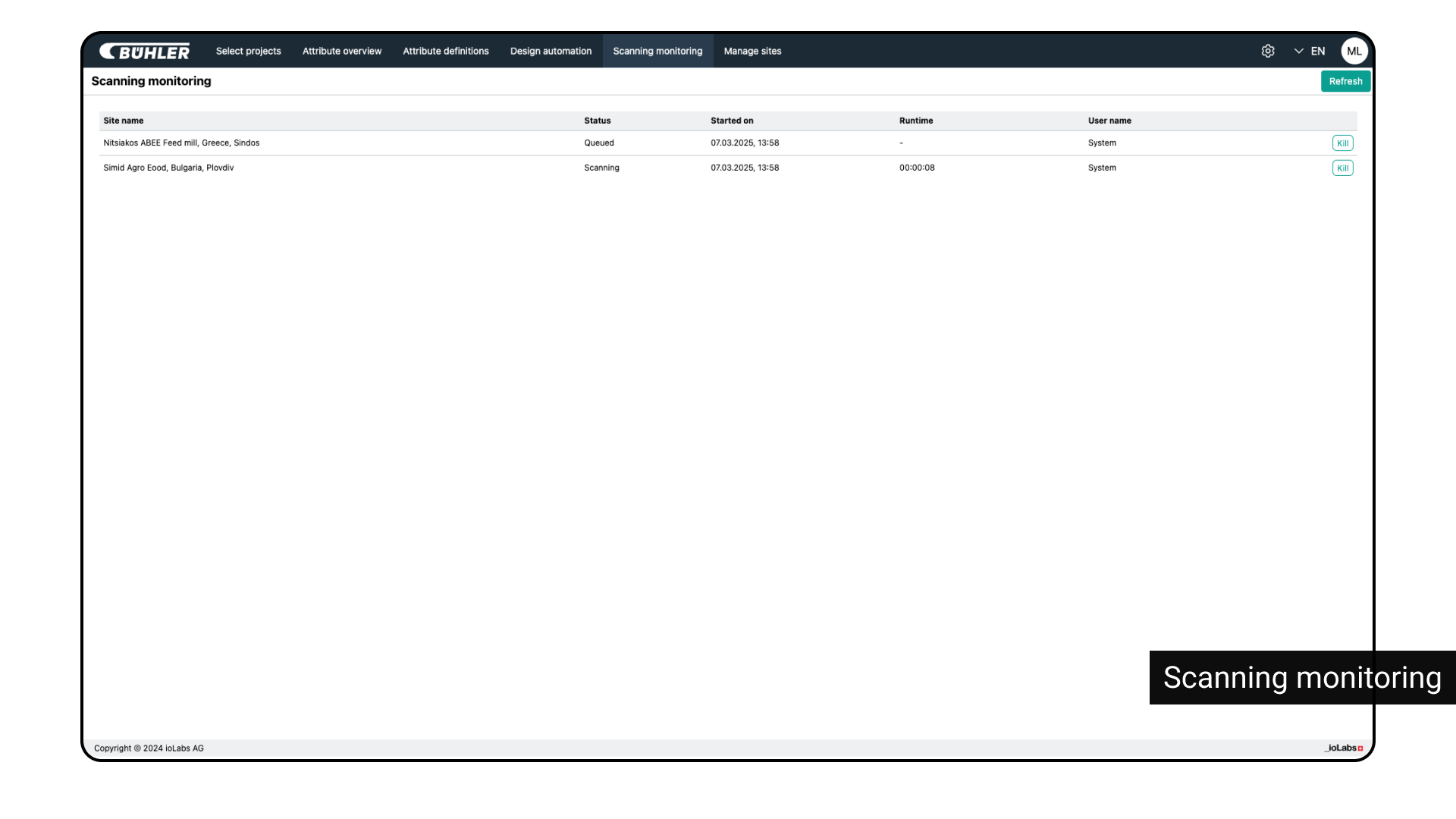

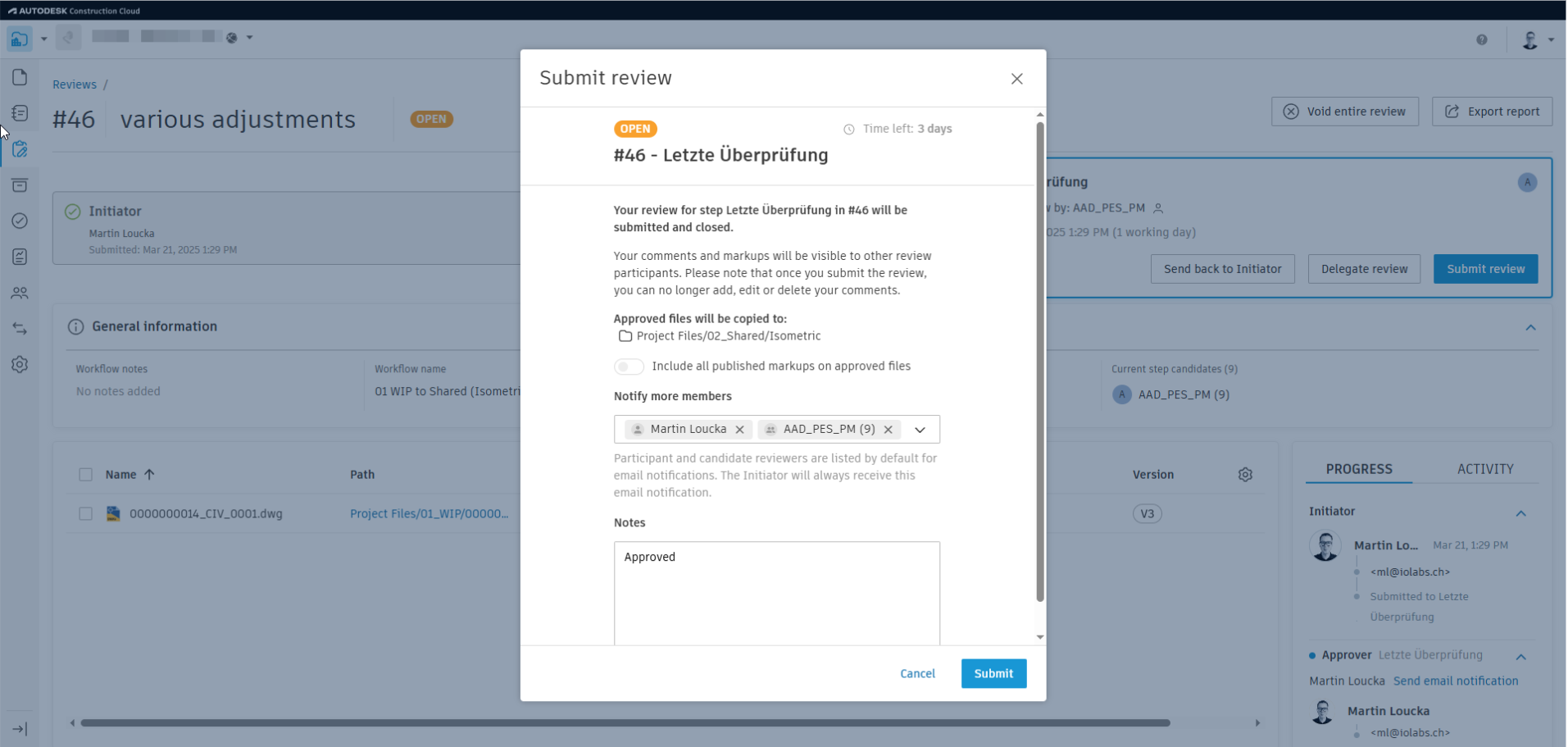

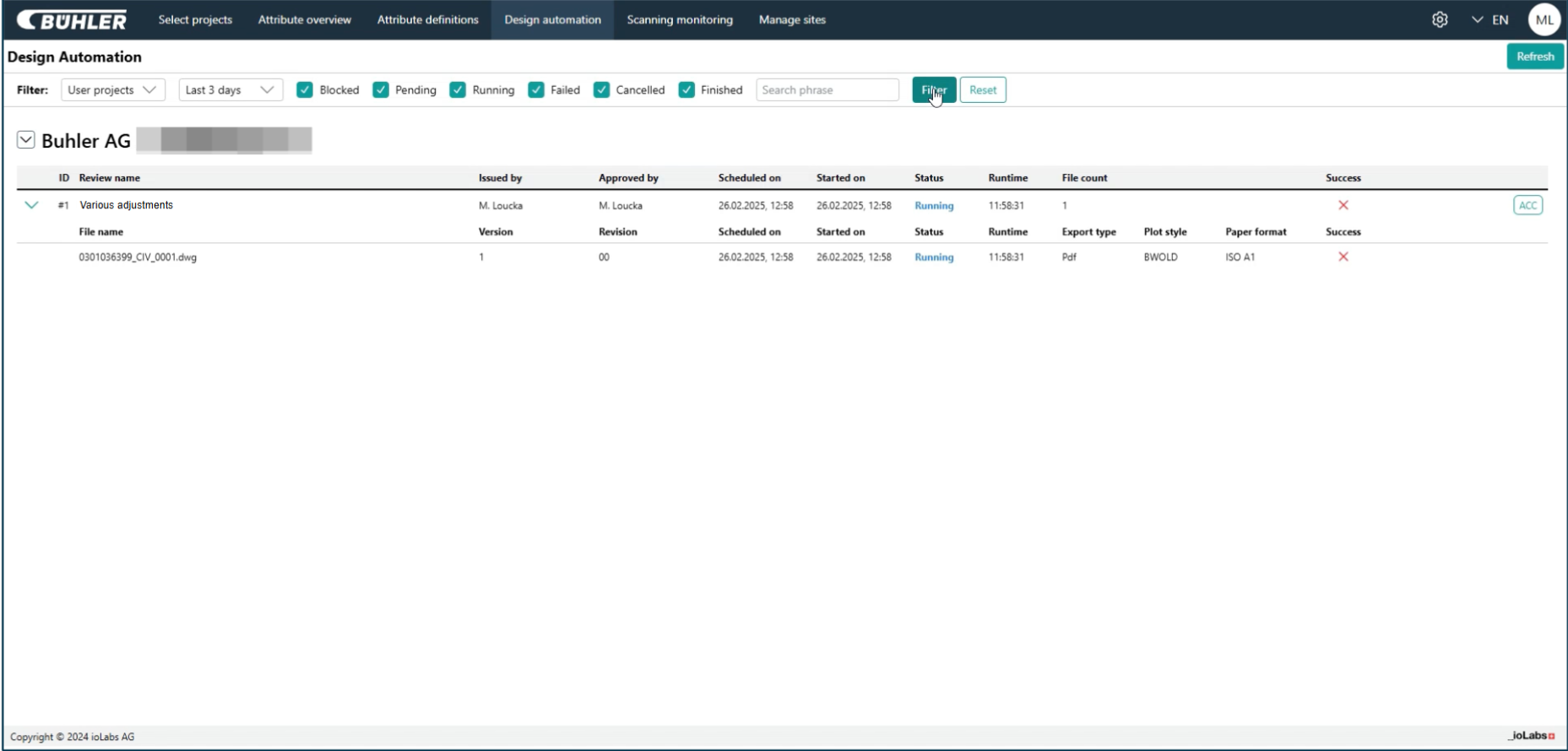

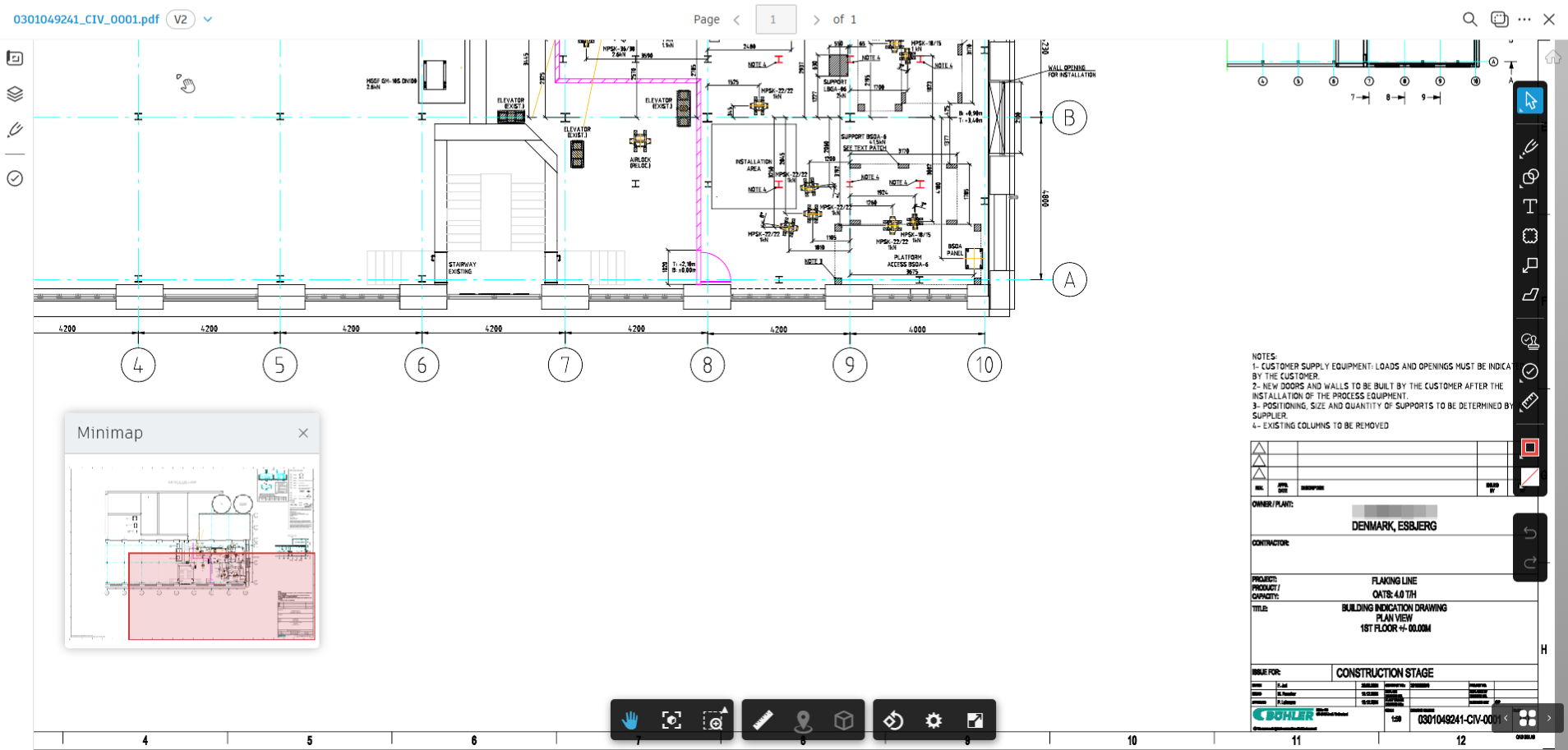

The solution introduced several key improvements. Drawing frames are now populated automatically, including support for over six languages. Plant3D and ACC projects are created and integrated without manual effort. Repeated attribute values can be updated in bulk, improving data accuracy and reducing time spent on editing - there are 1200 users in total and 900 Plant 3D users editing 2500 documents daily. PDF documents are generated automatically, triggered by ACC review workflows, and monitored via background services. A standardized file naming system has also been introduced, aligned with Bühler’s internal conventions to support long-term maintainability. Following implementation, Bühler achieved significant improvements in operational efficiency. More than 10,000 PDF files are now generated automatically each month. Approximately 2000 projects are initiated annually, and over 900 engineers and 300 project managers worldwide work with the tools on a daily basis.

Business Outcomes

The solution has established a consistent, end-to-end workflow - from initial design to final deliverables - across Bühler’s engineering environment. Standardized drawing frames are now applied to over 4000 projects across 140 countries, ensuring uniformity across regions and languages. The potential human mistakes are reduced thanks to the automated solutions. In addition to improved consistency and brand alignment, the system has enhanced project visibility, enabled better compliance with internal and industry standards, and improved process quality through system-guided workflows. Automation has contributed to lower project costs, faster turnaround times, and reduced manual workload - particularly in the generation of engineering documentation. Hierarchical attribute inheritance further supports long-term efficiency gains across high-volume project environments - with 2000 new projects planned per year.

Video

Gallery

Client

Bühler AG

Credits

ioLabs AG

|

Technology

C# .NET Core

C# .NET Framework

ioFramework

Plant3D SDK

React.JS

Siemens Comos

|